Graphene from Ethylene

June 5, 2017

As a young

scientist in

elementary school, most of my

scientific knowledge came from

library books, the

newspaper, and such

magazines as

Life and

Popular Science. It was in Popular science that I read how some

fruits could be

ripened by exposure to

ethylene gas. This ripening process works only on

climacteric fruits, such as

tomato,

apple,

melon and

banana, and it doesn't work on non-climacteric fruits such as

citrus,

grapes, and

strawberries.

While some might consider this process to be another insidious way for

corporate agriculture to fool both us and

Mother Nature, we would not have such a variety of fruits available to use without it. Using this process, fruits can be

harvested before ripening,

shipped long distances, and appear at our local

supermarket in a form that we enjoy

eating. This is most apparent for bananas, which need to travel extreme distances to reach

Tikalon's Northern New Jersey home, so they're picked while still green and exposed to ethylene somewhere in transit.

Ethylene.

Elthylene, which is also called ethene, is the smallest alkene molecule.

(Modified Wikimedia Commons image by Origami-Kranich.)

As you likely guessed, ethylene is the

reagent for making

polyethylene. More than half of ethylene production is used to make polyethylene, the most widely used

polymer.

High-density polyethylene (HDPE), a

material used in many of my

grandchildren's toys, has a high

ratio of

strength to

density. This arises from the low degree of

branching in the polyethylene polymer that results in larger

intermolecular forces between the

polymer chains. HDPE is commonly used in

food storage containers,

plastic bottles, and

Tyvek barrier films used in

construction.

Graphene, a material formed as a monolayer of

carbon atoms, has been a popular

nanoscale material to

research in the last few

decades. Its potential as a useful

electronic and

structural material is underscored by the short span of time between its discovery and the award of a

Nobel Prize to its discoverers,

Andre Geim and

Konstantin Novoselov. These physicists first

published a paper on graphene in 2004, and they received the 2010

Nobel Prize in Physics.

I've written quite a few articles on this wonder material, the most recent of which can be viewed

here (Soybean Graphene, March 23, 2017). That article discussed a novel technique for graphene

synthesis developed by

Australian scientists from

CSIRO Manufacturing (Lindfield, New South Wales, Australia), the

University of Sydney (Sydney, Australia), the

University of Technology (Sydney, Australia), and

Queensland University of Technology (Brisbane, Australia). Their process used

soybean oil as a

precursor to graphene.

While graphene is typically grown using

chemical vapor deposition techniques, an international research team with members from the

Technische Universität München (Garching, Germany), the

University of St. Andrews (St. Andrews, United Kingdom), and the

Georgia Institute of Technology (Atlanta, Georgia) has examined production of graphene by assembly of

adsorbed molecules of ethylene on the (111)

crystal facet of

rhodium. They report their results in an

open access article in the

Journal of Physical Chemistry C.[1-3]

This graphene synthesis technique is inspired by the common process of

coking in which

organic compounds will transform to carbon when adsorbed onto

metal surfaces.[1] While coking is important in

steelmaking, it's also a nuisance in

catalysis, since it

poisons the catalytic surface.[1] The present process utilizes this coking process on a catalyst in which heated

one-dimensional polyaromatic hydrocarbons (1D-PAH) are converted into

two-dimensional molecules.

Surface diffusion allows

coalescence of these molecules into graphene.[1]

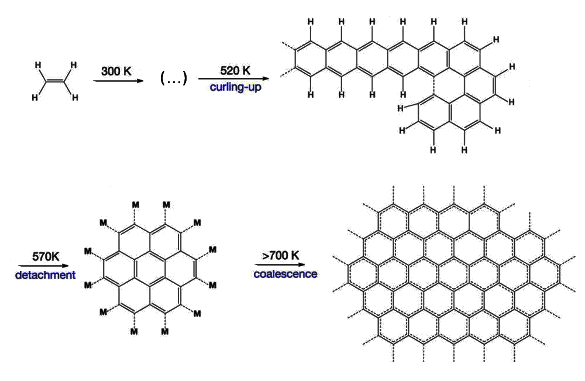

Surface reactions leading to graphene on the (111) crystal face of rhodium. The reactions start with ethylene, which is converted at various temperature stages, as shown. Some early steps up to 520 K are omitted for clarity. (Georgia Institute of Technology image by F. Esch, R. Schaub, and U. Landman.)

Some earlier efforts to produce graphene from simple

hydrocarbon precursors created

soot, as would be expected in a coking process, rather than graphene.[2] The trick was to heat the ethylene in stages, finally to a higher temperature than before. This resulted in pure layers of graphene on the rhodium surface.[2] As ethylene lost

hydrogen atoms, the remaining carbon atoms

self-assembled into the

honeycomb bonding of graphene.[2]

On initial heating above room temperature, the ethylene links into one-dimensional

chains of polyaromatic hydrocarbons. Additional heating caused these chains to

crosslink into two-dimensional molecules that surface-diffuse and coalescence into high purity graphene.[2] As

Uzi Landman, a

professor of

physics at the Georgia Institute of Technology who led the

theoretical component of this research,

"The temperature must be raised within windows of temperature ranges to allow the requisite structures to form before the next stage of heating... If you stop at certain temperatures, you are likely to end up with coking."[2]

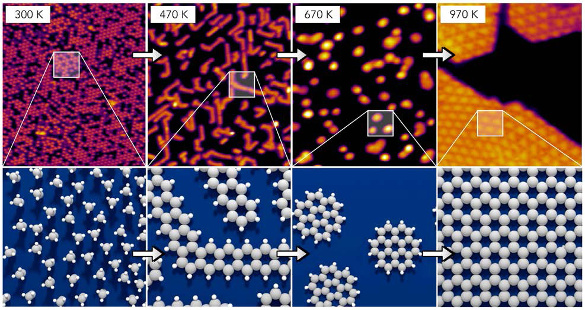

To understand the process, the research team used

scanning-tunneling microscopy,

high-resolution electron energy loss spectroscopy, and

thermally programmed desorption to observe and characterize the surface components at each process step.[2]

Dehydrogenation was an important step, but not all hydrogen is removed at once. Some of the hydrogen remains, and it aids the bond-breaking process that detaches the larger molecule precursors and allows them to become mobile.[2]

Scanning-tunneling microscope images of graphene formation from ethylene (top), and atomic models of what's happening (bottom). (Image by R. Schaub, licensed under the Creative Commons Attribution 4.0 International license.)

While this graphene synthesis technique is simple and potentially a lower

cost alternative to chemical vapor deposition, the problem remains that the graphene is attached to the rhodium

substrate and must be removed.[2] This research was funded by the

Air Force Office of Scientific Research and the

Office of Basic Energy Sciences of the

U.S. Department of Energy.[2]

References:

- Bo Wang, Michael König, Catherine J. Bromley, Bokwon Yoon, Michael-John Treanor, José A. Garrido Torres, Marco Caffio, Federico Grillo, Herbert Früchtl, Neville V. Richardson, Friedrich Esch, Ueli Heiz, Uzi Landman, and Renald Schaub, "Ethene to Graphene: Surface Catalyzed Chemical Pathways, Intermediates, and Assembly," J. Phys. Chem. C, vol. 121, no. 17 (March 14, 2017), pp. 9413-9423, DOI: 10.1021/acs.jpcc.7b01999. This is an Open access article with a PDF version available here.

- John Toon, "High Temperature Step-by-Step Process Makes Graphene from Ethene," Georgia Institute of Technology Press Release, May 4, 2017.

- Scanning-tunneling microscope video of ethylene decomposition at 455 K and subsequent polyaromatic hydrocarbon formation.

Permanent Link to this article

Linked Keywords: Scientist; elementary school; science; scientific; knowledge; public library; book; newspaper; magazine; Life magazine; Popular Science; fruit; ripening; ripen; ethylene; gas; climacteric; tomato; apple; melon; banana; citrus; grape; strawberry; corporate farming; corporate agriculture; Mother Nature; harvest; harvested; shipped; supermarket; eat; eating; Tikalon; Northern New Jersey; alkene; molecule; Wikimedia Commons; Origami-Kranich; reagent; polyethylene; polymer; high-density polyethylene; material; grandchild; toy; ratio; strength of materials; density; branching (polymer chemistry); van der Waals force; intermolecular force; polymer chain; food storage container; plastic bottle; Tyvek; membrane; barrier film; construction; graphene; carbon; atom; nanoscopic scale; nanoscale; research; decade; electronic; structural material; Nobel Prize; Andre Geim; Konstantin Novoselov; scientific literature; publish; Nobel Prize in Physics; soybean graphene; chemical synthesis; Australia; Australian; scientist; CSIRO Manufacturing (Lindfield, New South Wales, Australia); University of Sydney (Sydney, Australia); University of Technology (Sydney, Australia); Queensland University of Technology (Brisbane, Australia); soybean oil; precursor; chemical vapor deposition; Technical University of Munich; Technische Universität München (Garching, Germany); University of St. Andrews (St. Andrews, United Kingdom); Georgia Institute of Technology (Atlanta, Georgia); adsorption; adsorb; crystal facet; rhodium; open-access journal; open access article; Journal of Physical Chemistry C; coke; coking; organic compound; metal; steelmaking; catalysis; catalyst poisoning; one-dimensional; polycyclic aromatic hydrocarbon; polyaromatic hydrocarbon; two-dimensional; surface diffusion; coalescence; chemical reaction; graphene; Miller index; (111) crystal face; temperature; kelvin; K; F. Esch, R. Schaub, and U. Landman; hydrocarbon; soot; hydrogen; self-assembly; self-assemble; honeycomb; chemical bond; bonding; polymer architecture; chain; crosslink; Uzi Landman; professor; physics; theory; theoretical; scanning-tunneling microscopy; high-resolution electron energy loss spectroscopy; thermally programmed desorption; dehydrogenation; atom; atomic; Creative Commons Attribution 4.0 International license; cost; substrate; Air Force Research Laboratory; Air Force Office of Scientific Research; Office of Basic Energy Sciences; U.S. Department of Energy.