Carbon Thread

January 21, 2013

Carbon seems to be the most

researched element of the past few years, supplanting

silicon which brought us into a new

electronic age.

Graphene, one of the many

allotropic forms of carbon, is being researched for electronic applications. I wrote about the amazingly short interval between the discovery of graphene and the award of a

Nobel Prize for its discovery in a

previous article (2010 Nobel Prize in Physics, October 6, 2010).

Other allotropes of carbon,

carbon nanotubes (CNTs), are being researched for both electronic and

structural applications. The regular arrangement of

carbon atoms in nanotubes, combined with the 346

kJ/

mole bond energy of the

carbon-carbon bond, leads to a high

strength material. The

Young's modulus of

single-walled CNTs is about 1000

GPa; and their

tensile strengths are close to fifty GPa.[1]

Carbon nanotubes have desirable properties beyond their strength. They have low

density, high

electrical conductivity, and high

thermal conductivity. Nature, however, requires a little work from

scientists before CNTs can replace the structural materials we presently use. The practical problem is that CNTs are individually very small, so you need to assemble many of them together to get a macroscopic

fiber or

ribbon from which

composites can be made.

In an article at the end of last year (

Strong Carbon Nanotube Composites, November 12, 2012), I wrote about research in the dry-

drawing of carbon nanotubes into electrically-conductive sheets. These sheets were formed into

composites of high electrical conductivity and tensile strengths of 1.8 GPa, improved to 3.8 GPa by stretching.[2-5] The best such material had a Young's modulus as high as 293 GPa, a tensile strength of 3.8 GPa, a thermal conductivity of 41 W-m

−1-K

−1, and an electrical conductivity of 1230 S-cm

−1.[5]

A method of producing

threads of carbon nanotubes has just been published in

Science by an international team from the

Departments of Chemical and Biomolecular Engineering,

Chemistry,

Electrical and Computer Engineering,

Physics and Astronomy, the

Applied Physics Program, and

The Smalley Institute for Nanoscale Science and Technology at

Rice University (

Houston, Texas),

Technion-Israel Institute of Technology and the

Russell Berrie Nanotechnology Institute (

Haifa, Israel),

Teijin Aramid (

Arnhem, Netherlands), and the

Air Force Research Laboratory (

Wright-Patterson Air Force Base, Ohio).[6-7]

Says

Matteo Pasquali, research team leader and a

professor of chemical and biomolecular engineering and chemistry at Rice, "It looks like black cotton thread but behaves like both metal wires and strong carbon fibers."[6] These carbon nanotube threads have about the same thermal conductivity as, and an order of magnitude greater electrical conductivity than, the best

graphite fibers. Graphite fibers are

brittle, but the CNT threads are as flexible as textile thread. The electrical conductivity is like that of

copper,

gold and

aluminum.[6]

Conductive and strong.

This fifty gram light fixture is suspended by carbon nanotube threads that also provide the electrical current to power the LED lamp.

(Rice University Image, used with permission.)

A wet

spinning process is used to create the CNT threads. The key to the process was the discovery that CNTs are highly

soluble in

chlorosulfonic acid.[6] A concentrated solution of CNTs allows the same type of wet spinning process used for other fibers. The wet spinning process produces CNT fibers with good alignment of the fibers and a high fiber

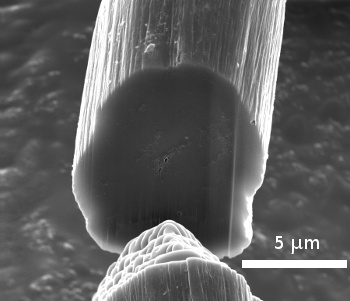

packing, as shown in the

scanning electron micrograph, below.[6]

scanning electron micrograph of a carbon nanotube thread.

This cross section of a fiber produced by the Rice University-Teijin Aramid process shows few voids within the fiber.

(Rice University Image, used with permission.)

The wet-spun CNT threads are about 10

μm in diameter, and they are built from a parallel alignment of tens of millions of CNTs. Strength and alignment are highly

correlated, so a close alignment of the CNTs is important.[6]

Rice University teamed with a manufacturer of commercial

aramid fiber, Teijin Aramid (Arnhem, Netherlands), to improve the wet spinning process. Teijin Aramid's involvement began in 2010, when they provided funding and access to their own scientists. Additional funding was provided by the Air Force Office of Scientific Research, Technion's Russell Berrie Nanotechnology Institute, the

US Department of Defense, and the

Welch Foundation.[6]

Wet-spun carbon nanotube thread on a spool.

(Still from a YouTube video.)[8]

![]()

References:

- S. Bellucci, "Carbon nanotubes: physics and applications," Physica Status Solidi (c), vol. 2, no. 1 (January 2005), pp. 34-47.

- K.L. Jiang, Q.Q. Li and S.S. Fan, "Nanotechnology: Spinning continuous carbon nanotube yarns – Carbon nanotubes weave their way into a range of imaginative macroscopic applications," Nature, vol. 419, no. 6909 (October 24, 2002), pp. 801.

- Wei Liu, Xiaohua Zhang, Geng Xu, Philip D. Bradford, Xin Wang, Haibo Zhao, Yingying Zhang, Quanxi Jia, Fuh-Gwo Yuan, Qingwen Li, Yiping Qiu and Yuntian Zhu, "Producing superior composites by winding carbon nanotubes onto a mandrel under a poly(vinyl alcohol) spray," Carbon, vol. 49, no. 14 (November 2011), pp. 4786-4791.

- Matt Shipman, "New Techniques Stretch Carbon Nanotubes, Make Stronger Composites," North Carolina University Press Release, October 15, 2012.

- X. Wang, Z. Z. Yong, Q. W. Li, P. D. Bradford, W. Liu, D. S. Tucker, W. Cai, H. Wang, F. G. Yuan and Y. T. Zhu, "Ultrastrong, Stiff and Multifunctional Carbon Nanotube Composites," Materials Research Letters, 2012; Open Access PDF File available here.

- Jade Boyd, "New nanotech fiber: Robust handling, shocking performance," Rice University Press Release, January 10, 2013.

- Natnael Behabtu, Colin C. Young, Dmitri E. Tsentalovich, Olga Kleinerman, Xuan Wang, Anson W. K. Ma, E. Amram Bengio, Ron F. ter Waarbeek, Jorrit J. de Jong, Ron E. Hoogerwerf, Steven B. Fairchild, John B. Ferguson, Benji Maruyama, Junichiro Kono, Yeshayahu Talmon, Yachin Cohen, Marcin J. Otto and Matteo Pasquali, "Strong, Light, Multifunctional Fibers of Carbon Nanotubes with Ultrahigh Conductivity," Science, vol. 339 no. 6116 (January 11, 2013), pp. 182-186.

- Spinning nanotube fibers at Rice University, YouTube Video, January 10, 2013.

Permanent Link to this article

Linked Keywords: Carbon; research; chemical element; silicon; electronics; graphene; allotropes of carbon; allotropic; Nobel Prize; carbon nanotube; structural material; carbon; atom; joule; kJ; mole; bond energy; carbon-carbon bond; ultimate tensile strength; Young's modulus; single-walled CNTs; pasca; GPa; density; electrical conductivity; thermal conductivity; scientist; fiber; ribbon; composite; drawing; thread; Science; Departments of Chemical and Biomolecular Engineering; Chemistry; Electrical and Computer Engineering; Physics and Astronomy; Applied Physics Program; The Smalley Institute for Nanoscale Science and Technology; Rice University; Houston, Texas; Technion-Israel Institute of Technology; Russell Berrie Nanotechnology Institute; Haifa, Israel; Teijin Aramid; Arnhem, Netherlands; Air Force Research Laboratory; Wright-Patterson Air Force Base, Ohio; Matteo Pasquali; professor; graphite fiber; brittleness; brittle; copper; gold; aluminum; gram; electrical current; LED lamp; spinning; solubility; soluble; chlorosulfonic acid; relative density; packing; scanning electron micrograph; micrometer; μm; correlation and dependence; aramid fiber; US Department of Defense; Welch Foundation; YouTube.