Heat Transfer

September 28, 2020

Everybody seems to

love duct tape. Its name derives from its intended use as a means to

seal joints in

air ducts, but the variant on its name,

duck tape, comes from one of the original

materials of its

manufacture,

duck cloth, which is a heavy,

plain woven cotton fabric. It's often recommended that

automobile drivers include a roll of duct tape in their automobile

emergency repair kit, since it's useful for temporarily attaching loose

parts and stopping

leaks in

radiator hoses.

I was happy to have some duct tape in my

car many years ago when

steam emerged from under the

hood, a sure sign of radiator hose

rupture. An automobile radiator is designed to "radiate"

heat developed in the

engine; but, in a strict

physics sense, automobile radiators

transfer just a little heat to the

environment by

radiation, the major transfer being done through

conduction.

Air flow through the radiator

fins, caused by motion of the automobile or by an

electric fan, transfers heat from the radiator to

air through contact with the

metal, which is in contact with the

engine coolant.

A Ford Model T touring car, 1925.

The Model T, the first affordable automobile, was produced from 1908 through 1927 using assembly line mass production techniques. Sixteen and a half million Model T automobiles were sold.

The first production units had a radiator, and also a coolant pump as in modern automobiles. Later units used thermosiphon flow of coolant instead of a pump to transport coolant to the radiator.

(Modified Wikimedia Commons image by Lars-Göran Lindgren.)

Radiators are required for automobiles, since the fraction of heat

energy of their

internal combustion engine that's converted to useful

work is small. This fraction is called the

thermal efficiency, and it's only about 25-35% in today's automobiles, so 65-75% of

fuel is merely

burned to create unwanted heat. About half of this

waste heat is transferred to the environment through the hot

exhaust gas, and the other half through the radiator.

The reason for all this heat in automobile engines and other engines is a consequence of a fundamental principle of

thermodynamics that you need a

temperature difference to do

work. This was discovered in 1824 by

Sadi Carnot in his investigation of

heat engines, and this principle is codified in the

second law of thermodynamics. Carnot defined a maximum

efficiency,

η, as

η = 1 - (TC/TH)

where T

C is the temperature of a cold

reservoir, and T

H is the temperature of a hot reservoir. When there is no temperature differential, T

H is equal to T

C, and the efficiency is zero.

The formal name for a

radiator found in automobiles and other equipment is a

heat exchanger. Heat exchangers transfer heat between two or more

fluids, and an automobile radiator exchanges heat between a first fluid, the engine coolant, and a second fluid, air. Many homes have

central air conditioning with an outside heat exchanger. Inside the house, heat from indoor air transforms a cool

refrigerant liquid to a hotter

gas. Outside the house, the refrigerant gas is

compressed and passed through a large

coil, called a

condenser coil, that's

thermally coupled to

metal fins that expel heat to the environment and turn the refrigerant back to a liquid.

Conventional wisdom says that the

efficiency of heat exchangers in

residential central air conditioners will be hampered by

dirty fins, since dirt will reduce air flow and act as a

thermal barrier coating. Thermal barrier coatings are used to good advantage on

gas turbine engine blades, since they allow a higher operating temperature, and engine efficiency increases as temperature increases. Any thermal barrier in a heat exchanger would defeat its purpose, so people will periodically clean their outside condenser units with a

water spray from a

garden hose.

A Siemens turbine engine blade with a thermal barrier coating.

High performance blades such as this have small holes for air cooling of the blade material.

(Wikimedia Commons photo by Bin im Garten. Click for larger image.)

While folk wisdom is considered true since it often has a convincing enough explanation,

scientists demand better

proof, and that's proof through

experiment.

David Yuill, an

assistant professor of

architectural engineering at the

University of Nebraska-Lincoln, and Mehdi Mehrabi, an architectural engineering

graduate student, conducted a study of how dirt might impeded the functioning of residential air conditioning.[2] Their study was funded by the

American Society of Heating, Refrigerating, and Air-conditioning Engineers, of which Yuill is a member.[2]

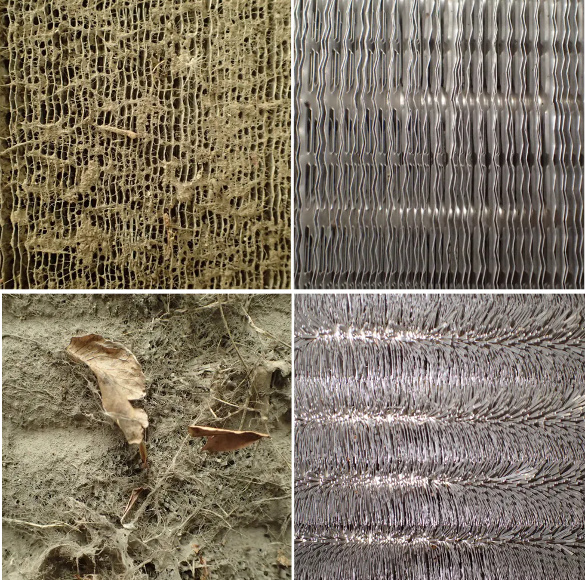

Yuill and Mehrabi removed condensers coated with real-world dust from residential air conditioning systems, and tested their performance in a

laboratory. They then cleaned these with water and a

commercial coil cleaning fluid, took note of the quantity of dirt removed, and retested them to find the difference in cooling capacity. Two examples appear in the figure, below.

Residential central air conditioning condenser heat exchanger fins, dirty and clean. Upper images show condenser fins with 7 grams of dirt per square foot before and after cleaning, while the lower images are for 17 grams of dirt per square foot. Note the poor state of the metal fins in the image at the lower right, which might be the result of too aggressive a cleaning. (Images by Mehdi Mehrabi from ref. 2, released under a Creative Commons License.[2] Click for larger image.)

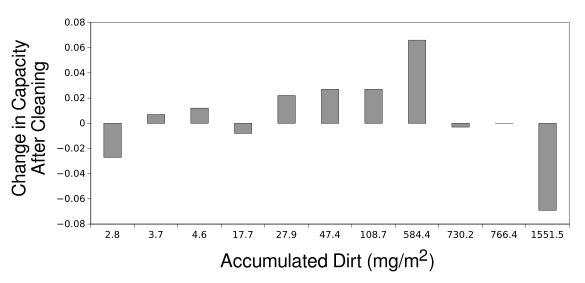

The

researchers found that, contrary to expectations, pre-cleaned air conditioner condensers sometimes perform better than clean ones. The

experimental findings, as shown in the

chart, had the change in condenser coil heat transfer performance after cleaning range from a 7% increase to a 7% decrease, with an

average change of essentially zero. While a condenser with 7 grams of dirt per square foot (585

mg/

m2) showed a 7% improvement in function with cleaning, another with 17 grams of dirt per square foot (1550 mg/m

2) had a 7% worse performance after cleaning.[2]

Air conditioner condenser performance change with cleaning. (Created using Gnumeric from data in ref. 2.)

The study conclusion is that cleaning your air conditioner condenser might make it more efficient, and it might make it less efficient. Since cleaning doesn't appear to make any difference, skipping this task shouldn't make you feel

guilty. However, Yuill admits he will still clean his when it's so dirty that he can't see the metal fins. As Yuill writes,

"As news of our findings spreads, I’m bracing for some unpleasant responses from people who might lose out if the condenser-cleaning business dries up and others who simply refuse to accept that there was no basis for the conventional wisdom on this question."[2]

References:

- Jerald A. Caton, "Thermodynamics of Internal Combustion Engines: Examples of Insights," Inventions, vol. 3, no. 2, pp. 33ff., https://doi.org/10.3390/inventions3020033. This is an open access article with a PDF file here.

- David Yuill, "Skip this chore: Cleaning your air conditioner condenser probably won’t make it work better," The Conversation, March 22, 2019

Linked Keywords: Love; duct tape; seal (mechanical); joint (mechanical); duct (flow); air duct; material; manufacturing; manufacture; cotton duck; duck cloth; plain weave; plain woven; cotton; textile; fabric; automobile; driver; emergency repair kit; interchangeable parts; leak; radiator (engine cooling; hose (tubing); car; steam; hood (car); rupture; heat; internal combustion engine; physics; heat transfer; environment (biophysical); thermal radiation; conduction (heat); airflow; fin; electric fan; air; metal; antifreeze; engine coolant; Ford Model T; touring car; assembly line; mass production; coolant pump; thermosiphon; Wikimedia Commons; energy; work (physics); thermal efficiency; motor fuel; combustion; burned; waste heat; exhaust gas; thermodynamics; temperature; work (thermodynamics); Sadi Carnot; heat engine; second law of thermodynamics; efficiency; thermal reservoir; heat exchanger; fluid; central air conditioning; refrigerant; liquid; gas; compression (physical); coil (chemistry); condenser (heat transfer); thermal conductivity; thermally coupled; metal; fin; folklore; conventional wisdom; efficiency; residence; residential; dirt; dirty; thermal barrier coating; gas turbine engine; turbine blade; water; spray (liquid drop); garden hose; Siemens; hole; air cooling; material; Bin im Garten; folk wisdom; scientist; models of scientific inquiry; proof; experiment; David Yuill; assistant professor; architectural engineering; University of Nebraska-Lincoln; postgraduate education; graduate student; ASHRAE; American Society of Heating, Refrigerating, and Air-conditioning Engineers; laboratory; commerce; commercial; gram; square foot; Creative Commons License; research; researcher; experimental; bar chart; average; mass; mg; meter; Gnumeric; guilt (emotion); guilty.