Formica

May 14, 2018

I started building

electronic circuits in the final years of

vacuum tube electronics. Vacuum tubes served the

amplification function that is now done with

transistors. The

integrated circuits of today contain

tens of billions of transistors, a considerable fraction of the number of

stars of our

Milky Way Galaxy, while a popular

consumer radio receiver of the

mid-20th century, the "

All American Five," had just five vacuum tubes.

All American Five radio receiver, circa 1947.

This Emerson AM Table Radio, Model 547A, had the following five 7-pin miniature tube complement: 35W4 (rectifier), 12BE6 (superheterodyne converter), 12BA6 (IF amplifier), 12AT6 (detector and first audio amplifier), and 50B5 (audio power amplifier).

The tube complement of earlier All American Five radios had a 35Z5 rectifier, 12SA7 superheterodyne converter, 12SK7 IF amplifier, 12SQ7 detector and first audio amplifier, and 50L6 audio power amplifier.

(Wikimedia Commons image by Joe Haupt)

Man makes good use of

natural materials, and this was evident in early electronics. While

cotton as

wire insulation was replaced very early by

polymers, the

mineral,

mica, has excellent

dielectric properties, and it was used in

capacitors into the last half of the 20th century. The particular mica used in capacitors was

muscovite, a

monoclinic crystal with a

perfect basal cleavage that allows its separation into large, thin sheets on

{001} planes. The

chemical composition of muscovite is KAl

2(AlSi

3O

10)(F,OH)

2.

Mica was used in capacitors since its

dielectric constant can be as high as 9.3,[1] it has an extremely high

dielectric strength of ~100

V/

μm, and its

crystals can be huge, thereby yielding large sheets of dielectric. Since mica is composed of

elements with small

atomic number, it's relatively

transparent to

alpha particles, so it's used as a

window on

Geiger-Müller tubes in "Geiger" counters.

Component designers crave uniformity, so

industrial materials are preferred over natural materials. In 1913, Daniel J. O'Conor, Jr.

patented a mica substitute for

electrical equipment manufacturer,

Westinghouse.[2] This mica substitute with a dielectric constant of about four was called

Formica. It was a

laminate of

paper or

textile bonded by

phenolic resin, and the Formica name derived from a combination of mica and the

formaldehyde component of phenolic resin.

Two examples of Formica.

On the left, Formica was used by my father, a carpenter, to make me a case for an electronic music synthesizer keyboard in the 1970s. On the right, an example of Formicidae, in this case a European red wood ant, Formica rufa.

(Left image by the author. Right image, a Wikimedia Commons image by Richard Bartz.)

While his

patent presented a more conventional method of sheet lamination, O'Conor devised a more efficient method of forming this Formica

composite material. Fabric was coated with resin as it was wound on a

spindle, the roll was slit lengthwise to yield a curved sheet, and this sheet was pressed flat and

cured.[3] As is typical for such "

work for hire"

inventions, O'Conor was awarded a

dollar for his invention (My

employer in the

1980s gave us two dollars, an award that was later upgraded to

shares of

company stock).

O'Conor and a Westinghouse

sales engineer, Herbert A. Faber, immediately left Westinghouse to form a company to produce this material with an initial $7,500

investment (about $200,000 in

today's money).[3] This company was first named, Formica Products Company, but the name was soon changed to The Formica Insulation Company to reflect their principal product, a material for electrical insulation.[3]

Although initial production of Formica was for electrical insulation, the use of Formica for

automotive timing

gears was developed in the

1920s. In 1927,

wood-grained and

marble-textured laminates were developed for the decorative sheets that are usually associated with the Formica name.[3] In 1938, phenolic resin was replaced by the superior

melamine resin.

Thermosetting melamine resin, developed by

American Cyanamid, was more

heat,

moisture, and

abrasion resistant than phenolic resin, and it could take more

colors.[3]

Melamine resin was invented by William F. Talbot of

Monsanto Chemical Company, and it was patented in 1941.[4] Melamine is notable for its use in

Melmac dinnerware prevalent through the

1970s. My wife and I were given Melmac dishes when we were

married. Melmac dinnerware was prone to

staining and

scratching, and the added problem that they were not

microwave-safe caused diminished sales. Melmac was still used for children's dinnerware, including the "

My Little Pony" dinner set that my

daughter had.

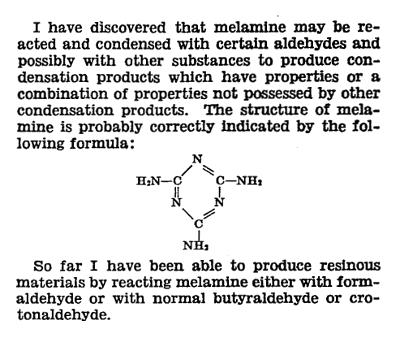

First portion of US Patent No. 2,260,239, "Manufacture of melamine-aldehyde condensation products," by William F. Talbot, October 21, 1941.

(Via Google Patents.[4])

It's interesting to examine the simplicity some of the early

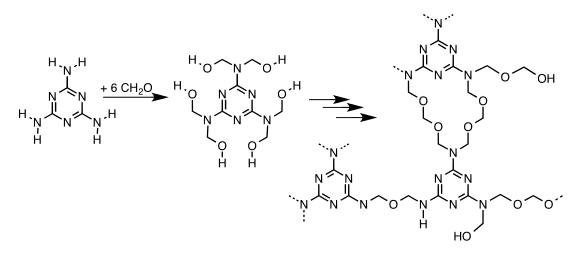

polymer reactions, and the melamine resin reaction is a good example. As shown below, you merely

condense formaldehyde (CH2O) with

melamine (C3H6N6) to form the

hexa-hydroxymethyl derivative. Heating this derivative in the presence of an

acid causes the

crosslinking that leads to a

high strength polymer.

Polymerization of melamine resin. Melamine is condensed with formaldehyde to form a hexa-hydroxymethyl derivative that forms the melamine resin polymer in the presence of an acid. (Wikimedia Commons image.)

References:

- J. R. Weeks, Jr., "The Dielectric Constant of Mica," Phys. Rev., vol. 19, no. 4 (April 1, 1922), pp. 319ff., DOI:https://doi.org/10.1103/PhysRev.19.319.

- Daniel J. O'conor, Jr., "Process of making composite material," U.S. Patent No. 1,284,432, February 1, 1913.

- Formica history, early years, from formica.com, via archive.org.

- William F. Talbot, "Manufacture of melamine-aldehyde condensation products," US Patent No. 2,260,239, October 21, 1941 (via Google Patents).

Linked Keywords: Electronic circuits; vacuum tube; amplifier; amplification function; transistor; integrated circuit; transistor count; tens of billions of transistors; stars; Milky Way Galaxy; consumer; radio receiver; mid-20th century; All American Five; Emerson Electric; miniature tube; 35W4; thermionic diode; rectifier; 12BE6; superheterodyne receiver; pentagrid converter; 12BA6; intermediate frequency; IF amplifier; 12AT6; detector (radio); audio amplifier; 50B5; audio power amplifier; 35Z5; 12SA7; 12SK7; 12SQ7; 50L6; Joe Haupt; Homo sapiens; Man; natural material; cotton; wire; electrical insulation; polymer; mineral; mica; dielectric; capacitor; muscovite; monoclinic; perfect basal cleavage; Miller index; {001} plane; chemical composition; relative permittivity; dielectric constant; dielectric strength; voltage; micrometer; μm; crystal; chemical element; atomic number; transparent; alpha particle; window; Geiger-Müller tube; electronic component; designer; industry; industrial; patent; patented; electrical equipment; manufacturing; manufacturer; Westinghouse Electric Company; Formica (plastic); laminate; paper; textile; phenol formaldehyde resin; phenolic resin; formaldehyde; father; carpenter; electronic music synthesizer; musical keyboard; 1970s; Formicidae; European red wood ant, Formica rufa; composite material; spindle; curing (chemistry); work for hire; invention; dollar; employment; employer; 1980s; share (finance); company stock; sales engineering; sales engineer; investment; time value of money; today's money; automobile; automotive; gear; 1920s; wood grain; marble-texture; melamine resin; thermosetting polymer; American Cyanamid; heat; moisture; mechanical abrasion; colors; Monsanto Chemical Company; Melmac dinnerware; 1970s; marriage; married; stain; scratch; microwave-safe; My Little Pony; daughter; Google Patents; polymerization; polymer reaction; condensation; condense; formaldehyde (CH2O); melamine (C3H6N6); hexa-hydroxymethyl; derivative (chemistry); acid; crosslink; strength of materials; high strength.