Graphene Putty

January 16, 2017

There are many examples of

materials research producing a different product than what was intended. One example is

WD-40, an

oil originally designed as a

corrosion-barrier coating for

metal, especially the

stainless steel fuel tanks of the

Atlas missile.[1] WD-40 is now an ubiquitous

household penetrating lubricant used for extracting

rusted bolts and many other applications. My favorite "

off-label" use is the removal of

adhesive residue, especially from old

duct tape, on compatible materials. The

WD-40 Web Site lists many more uses.[2]

The composition of WD-40 is a

trade secret, but its

ingredients,

as disclosed on Wikipedia, are as follow:

• 50% Aliphatic hydrocarbons.

• 25%, or less, mineral oil or light lubricating oil.

• 12-18% low vapor pressure aliphatic hydrocarbons. These reduce the low-viscosity to allow for spray application, and they evaporate quickly.

• 2-3% carbon dioxide, used as a flammability-retarding propellant.

• 10%, or less, inert ingredients.

Dupont chemist,

Stephanie Kwolek, was looking for a lightweight substitute for

steel wire in

radial tires when she discovered the

ultra-strong polymer,

Poly-paraphenylene terephthalamide, known as

Kevlar, which has a

tensile strength five times that of steel.

Belgian-

American chemist,

Leo Baekeland (1863-1944), was searching for a

synthetic replacement for the

natural product,

shellac, when he discovered

Bakelite, the first synthetic

thermosetting plastic. His "

insoluble product of

phenol and

formaldehyde" was commonly used as an

electrical insulator.[3]

Modern chemists are

safety conscious, and they wear

protective gloves when working with

chemicals. This wasn't the case in 1879 when

Constantin Fahlburg noticed a

sweet taste on his

hand after working with

coal tar reactions. He had discovered

saccharin, the first

artificial sweetener. Saccharin became important when

sugar supply became difficult during

World War I, and it was important for

sugar-free diets in later years.

The

Eastman Kodak company, the giant of

photography before its chemical phase was superseded by

digital photography, did more than adhere

silver halide to

film. Its

Kodak Research Laboratories did

research in many chemical areas, and it was there that Kodak

engineer,

Harry Coover discovered

cyanoacrylate "super-glue", a material originally tried as a clear plastic for

gun sights. This product was originally sold as "

Eastman 910."

As I wrote in an earlier article (

Silly Putty, August 6, 2014), research on a

natural rubber substitute during

World War II led to development of

Silly Putty® based on a mixture of

polydimethylsiloxane, [C

2H

6OSi]

n, and

silicone oil reacted with

boric acid.[4-5] Silly Putty® itself is a

trademarked name of a material sold by

Crayola, but similar materials sold under different names.[6] More than four thousand

tons of Silly Putty have been sold since 1950.[7]

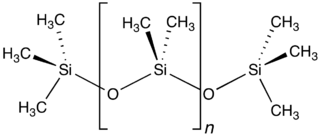

The structure of polydimethylsiloxane.

(Via Wikimedia Commons.)

Silly Putty has the unusual

mechanical characteristic that it can be slowly worked, like a

clay, but it behaves as an

elastic solid when the

rate of applied

force is large. This characteristic is a result of the

viscoelasticity of the polydimethylsiloxane.

According to Wikipedia, this is the composition of Silly Putty:

Dimethyl siloxane polymer, terminated with boric acid, 65%

Silica (crystalline quartz), 17%

Thixatrol ST (castor oil derivative), 9%

Polydimethylsiloxane, 4%

Decamethyl cyclopentasiloxane, 1%

Glycerine, 1%

Titanium dioxide, 1%

Silly putty is the basis of a novel

sensor material created by

physicists at the

School of Physics of

Trinity College Dublin (Dublin, Ireland) and the

University of Manchester (Manchester, UK). Silly putty mixed with

graphene exhibits an

electrical conductivity that varies with applied

force.[8-9] This research was enabled by a the €1 billion

Graphene Flagship initiative.[9] This research team has just

published their results in

Science.[8]

While graphene has been used as an additive in

nanocomposites, its behavior in highly

viscoelastic polymer

matrices has not been well characterized.[8] When graphene is added to silly putty, forming a material the research team calls "G-putty," the lightly

cross-linked polysilicone, its electromechanical properties are changed substantially.[8-9] There's a

post-deformation temporal relaxation of

electrical resistance and a nonmonotonic change in

resistivity with

strain.[8]

The

gauge factor of the material, the

ratio of the resistance change to the strain, is greater than 500. This compares with about 2-5 for metals, 30 for

polysilicon, and up to 100 for

thick film resistors of special compositions. The sensitivity is such that a force as small as a

spider's footstep can be detected.[9] While spider detection would be a niche application, the material could prove useful as a sensor for

respiration,

pulse rate, and

blood pressure.[9]

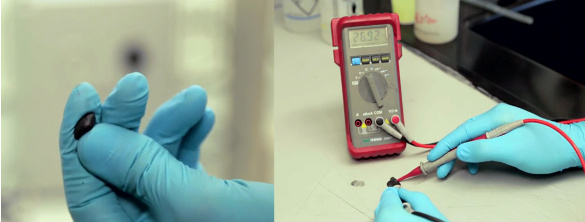

Graphene-filled silly putty (G-putty) is soft and flexible. It also exhibits a large resistance change with applied pressure. (Still images from a Trinity College Dublin video.)

While conductivity changes like this usually arise from

percolation, the electrical properties of G-putty appear to be associated with nanosheets of graphene moving in the

low-viscosity polymer matrix.[8] The research team was able to devise a

mathematical model that describes the electromechanical properties of G-putty.[8]

Says

Jonathan Coleman, a

professor at Trinity College Dublin,

"When we added the graphene to the silly putty, it caused it to conduct electricity, but in a very unusual way. The electrical resistance of the G-putty was very sensitive to deformation with the resistance increasing sharply on even the slightest strain or impact. Unusually, the resistance slowly returned close to its original value as the putty self-healed over time."[9]

Study co-author, Jonathan Coleman, and son, Oisin, playing with types of silly putty.

In Coleman's case, it's graphene-filled silly putty, G-putty.

(Trinity College Dublin image.)

References:

- WD-40 History, WD-40 Company, Inc., Web Site.

- List of 2000+ Uses of WD-40, WD-40 Company, Inc., Web Site (PDF File).

- Leo H Baekeland, "Method of making insoluble products of phenol and formaldehyde," US Patent No. 942,699, December 7, 1909.

- Mcgregor Rob Roy and Warrick Earl Leathen, "Treating dimethyl silicone polymer with boric oxide," US Patent No. 2,431,878, December 2, 1947.

- James G E Wright, "Process for making puttylike elastic plastic, siloxane derivative composition containing zinc hydroxide," US Patent No. 2,541,851, Feb 13, 1951.

- Maurice A. Minuto, "Method of Making Bouncing Silicone Putty-Like Compositions," US Patent No. 4371493, February 1, 1983.

- Eugene S. Robinson, "How That Pinkish Goo Called Silly Putty Came Out Of Its Shell," NPR, July 17, 2014.

- Conor S. Boland, Umar Khan, Gavin Ryan, Sebastian Barwich, Romina Charifou, Andrew Harvey, Claudia Backes, Zheling Li, Mauro S. Ferreira, Matthias E. Möbius, Robert J. Young, and Jonathan N. Coleman, "Sensitive electromechanical sensors using viscoelastic graphene-polymer nanocomposites," Science, vol. 354, no. 6317 (December 9, 2016), pp. 1257-1260, DOI: 10.1126/science.aag2879.

- State of the art sensors made from graphene and children's toy silly putty, Trinity College Dublin Press Release, December 8, 2016.

Permanent Link to this article

Linked Keywords: Materials science; materials research; WD-40; lubricant; oil; anti-corrosion; corrosion-barrier; coating; metal; stainless steel; fuel tank; Atlas missile; household; penetrating oil; penetrating lubricant; rust; rusted; bolt; off-label; adhesive; duct tape; trade secret; ingredient; Wikipedia; aliphatic hydrocarbon; mineral oil; vapor pressure; low-viscosity; aerosol spray; evaporation; evaporate; carbon dioxide; flame retardant; flammability-retarding; propellant; excipient; inert ingredient; Dupont; chemist; Stephanie Kwolek; steel; wire; radial tire; strength of materials; ultra-strong; polymer; Poly-paraphenylene terephthalamide; Kevlar; tensile strength; Belgium; Belgian; America; American; Leo Baekeland (1863-1944); chemical synthesis; synthetic; natural product; shellac; Bakelite; thermosetting polymer; thermosetting plastic; solubility; insoluble; phenol; formaldehyde; electrical insulator; safety; nitrile rubber; protective gloves; chemical compound; Constantin Fahlburg; sweetness; sweet taste; hand; coal tar; chemical reaction; saccharin; sugar substitute; artificial sweetener; sucrose; sugar; World War I; sugar-free diet; Eastman Kodak company; photography; digital photography; silver halide; film; Kodak Research Laboratories; research; engineer; Harry Coover; cyanoacrylate "super-glue"; gun sight; Eastman 910; natural rubber; World War II; Silly Putty®; polydimethylsiloxane; silicone oil; boric acid; trademark; Crayola; ton; Wikimedia Commons; mechanical characteristic; clay; elasticity; elastic; solid; rate; force; viscoelasticity; Dimethyl siloxane; polymer; terminate; boric acid; silicon dioxide; Silica; crystal; crystalline; quartz; castor oil; derivative; Decamethyl cyclopentasiloxane; Glycerol; Glycerine; Titanium dioxide; sensor; physicist; School of Physics; Trinity College Dublin (Dublin, Ireland); University of Manchester (Manchester, UK); graphene; electrical conductivity; force; Graphene Flagship initiative; scientific literature; publish; Science; nanocomposite; viscoelasticity; viscoelastic; composite material; matrix; cross-link; siloxane; polysilicone; deformation; temporal relaxation; electrical resistance; resistivity; strain; gauge factor; ratio; polysilicon; thick film resistor; spider; respiration; pulse rate; blood pressure; pressure; percolation theory; mathematical model; Jonathan Coleman; professor; co-author; son; Leo H Baekeland, "Method of making insoluble products of phenol and formaldehyde," US Patent No. 942,699, December 7, 1909; Mcgregor Rob Roy and Warrick Earl Leathen, "Treating dimethyl silicone polymer with boric oxide," US Patent No. 2,431,878, December 2, 1947; James G E Wright, "Process for making puttylike elastic plastic, siloxane derivative composition containing zinc hydroxide," US Patent No. 2,541,851, Feb 13, 1951; Maurice A. Minuto, "Method of Making Bouncing Silicone Putty-Like Compositions," US Patent No. 4371493, February 1, 1983.