Refining Germanium

June 22, 2017

One of my

brothers and I had the experience of working with Ernest ("Ernie") Buehler, he at

Bell Labs, and I at a

corporation whose name has been

expunged by a

merger and typical corporate

chessmanship. Ernie enjoyed

repairing small appliances for his

elderly lady friends, and he was

famous for his

potato bread. He was a

crystal grower, also famous for growing the

germanium crystal used in the

first transistor, invented at Bell Labs in December, 1947, by

John Bardeen (1908-1991),

William Shockley (1910-1989), and

Walter Brattain (1902-1987). This trio was awarded the 1956

Nobel Prize in Physics for this work. Buehler also grew the crystal for the first

silicon transistor.[1]

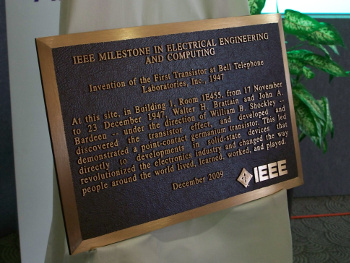

Commemorative plaque marking the demonstration of the transistor. This plaque was dedicated on December 8, 2009, during a ceremony at Bell Labs.

(My photo, via Wikimedia Commons. Click for larger image.)

While the

semiconductor of choice in today's world is silicon because of its better

temperature stability, germanium crystals are easier to grow, and this fact was especially important in the

1940s. Both silicon and germanium are prepared using the

Czochralski process in which a

seed crystal is dipped into a

crucible of

molten semiconductor just at the

melting point, and the seed grows larger when

rotated and pulled away at a slow rate. This method is used not just for semiconductors, but also for

laser materials such as

yttrium aluminum garnet (YAG, Y

3Al

5O

12).

The

Czochralski process is named after its

inventor,

Polish chemist,

Jan Czochralski. Czochralski wasn't interested in growing crystals; rather, he developed this process in 1916 in an attempt to produce

metal wire without

drawing.

Gordon Teal of Bell Labs adapted the process to the growth of germanium crystals that were used to fabricate

high frequency diodes during

World War II.

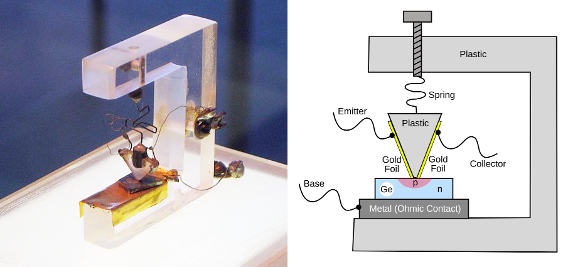

The first transistor wasn't a

junction transistor or

field effect transistor, both of which are now common. It was a

point-contact transistor, a type that was easy to demonstrate with the crude

laboratory equipment of the time. As shown in the figure, it was created by the contact of two closely-spaced

gold electrodes on a

slice of germanium crystal mounted on another electrode for

ohmic contact. The metal contacts form shallow

p-type regions in the overall

n-type germanium.

The first transistor was a point-contact transistor, improvised by Walter Brattain using a bent paper clip as a spring. In an amplifier circuit, a small current at the emitter generates a higher current between the base and collector. Once you have the germanium, the rest is relatively easy, a fact that shows the importance of materials science to progress in technology. (Left photo by Windell H. Oskay, via Wikimedia Commons; right image created using Inkscape. Another image of the first transistor can be found at archive.org)

When growing a crystal of germanium, or another

element or

compound, you need high

purity starting materials. The typical standard is "

five-nines;" that is, 99.999% pure, which is quite a step above

99 44/100% pure. Often, it's important that the 1000

ppm of impurities in such materials do not contain certain elements, such as

sodium.

Germanium is obtained as a

byproduct of

zinc refining from the chief

ore of zinc,

sphalerite, which is mostly

zinc sulfide (ZnS) with quite a few metal impurities substituting on the zinc

lattice sites in the crystal. One of these impurities is germanium, which generally exists at about 1000 ppm, but as high a

concentration as 3000 ppm in some ores.[2]

The

extraction process to separate germanium from zinc is not

environmentally friendly, since it uses

chlorine and

hydrochloric acid. Now, a team of

chemists from

McGill University (Montreal, Quebec, Canada), the

University of Western Ontario (London, Ontario, Canada), and

Soochow University (Suzhou, China) has developed an alternative process that uses a

recyclable quinone/

catechol redox reaction that uses

oxygen, rather than chlorine, as an

oxidizer to produce an air- and moisture-stable Ge(IV)-

catecholate that is converted to the high-purity germanium

organometallic compound,

germane.[3-4]

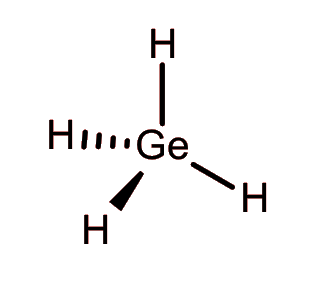

Germane.

This molecule is like methane, but with germanium as the central atom in place of carbon.

(Via Ref. 3.[3] Licensed under the Creative Commons Attribution-NonCommercial license.)

The inspiration for the process came from

biology. McGill University had been researching

melanin, the chemical that gives color to

skin and

hair and will also bind to metals.[4] The chemists decided to

synthesize a molecule that mimics such qualities of melanin to extract germanium at

room temperature without the use of

solvents.[4] Germanium is a good target for such research, since it's a useful element without a suitable substitute that exists as just a trace element in various ores.[3] Such compounds can be used to extract other metals, such as zinc,

copper,

manganese and

cobalt.[4]

Says

Jean-Philip Lumb, an

associate professor in the

McGill University Department of Chemistry.

"At a time when natural deposits of metals are on the decline, there is a great deal of interest in improving the efficiency of metal refinement and recycling, but few disruptive technologies are being put forth... That's what makes our advance so important... Applications of green chemistry lag far behind in the area of metals, yet metals are just as important for sustainability as any organic compound. For example, electronic devices require numerous metals to function."[4]

Their final process is green in more than one sense, since it also consumes far less energy than the conventional techniques.[3-4] One aspect of the process is the use of

mechanochemistry; that is, using

mechanical energy to promote

chemical reactions. The chemicals are shaken at high speed in

milling jars containing

stainless steel balls.[4-5]

Funding for this research was provided by the

Natural Sciences and Engineering Research Council of Canada, the

National Natural Science Foundation of China, and other agencies.

References:

- Oral-History:Goldey, Hittinger and Tanenbaum, Interview No. 480, IEEE History Center, The Institute of Electrical and Electronics Engineers, Engineering and Technology History Wiki, September 25, 2008.

- Nigel J. Cook, Barbara Etschmann, Cristiana L. Ciobanu, Kalotina Geraki, Daryl L. Howard, Timothy Williams, Nick Rae, Allan Pring, Guorong Chen, Bernt Johannessen, and Joël Brugger, "Distribution and Substitution Mechanism of Ge in a Ge-(Fe)-Bearing Sphalerite," Minerals, vol. 5 (March 24, 2015), pp. 117-132;, doi:10.3390/min5020117.

- Martin Glavinović, Michael Krause, Linju Yang, John A. McLeod, Lijia Liu, Kim M. Baines, Tomislav Friŝĉić, and Jean-Philip Lumb, "A chlorine-free protocol for processing germanium," Science Advances, vol. 3, no. 5 (May 5, 2017), Article e1700149, DOI: 10.1126/sciadv.1700149. This is an open access article with a PDF file available here.

- A more sustainable way to refine metals, McGill University Press Release, June 7, 2017.

- Solvent-free mechanochemical techniques..., YouTube Video by Michael Brand (University of Cardiff) and Jean-Louis Do (McGill University), June 6, 2017.

Permanent Link to this article

Linked Keywords: Brother; Bell Labs; corporation; expunge; merger; chessmanship; repair; small appliance; widow; elderly lady friend; famous; potato bread; crystal growth; crystal grower; germanium; crystal; first transistor; John Bardeen (1908-1991); William Shockley (1910-1989); Walter Brattain (1902-1987); Nobel Prize in Physics; silicon; transistor; commemorative plaque; semiconductor; temperature coefficient; temperature stability; 1940s; Czochralski process; seed crystal; crucible; melting; molten; melting point; rotation; rotate; laser; material; yttrium aluminum garnet; invention; inventor; Poland; Polish; chemist; Jan Czochralski; metal; wire; wire drawing; Gordon Teal; high frequency; diode; World War II; junction transistor; field effect transistor; point-contact transistor; laboratory equipment; gold; electrode; wafer; slice; electrical conductor; ohmic contact; p-type; n-type; paper clip; spring; amplifier; electrical network; circuit; electric current; emitter; base; collector; materials science; technology; evilmadscientist.com; Windell H. Oskay; Inkscape; archive.org; chemical element; chemical compound; impurity; purity; five-nines; Ivory (soap); 99 44/100% pure; parts-per notation; ppm; sodium; byproduct; zinc; extractive metallurgy; refining; ore; sphalerite; zinc sulfide (ZnS); crystal structure; lattice site; concentration; environmentally friendly; chlorine; hydrochloric acid; chemist; McGill University (Montreal, Quebec, Canada); University of Western Ontario (London, Ontario, Canada); Soochow University (Suzhou, China); recycling; recyclable; quinone; catechol; redox reaction; oxygen; oxide; oxidizer; catecholate; organometallic compound; germane; molecule; methane; atom; carbon; Creative Commons Attribution-NonCommercial license; biology; melanin; skin; hair; chemical synthesis; synthesize; room temperature; solvent; copper; manganese; cobalt; Jean-Philip Lumb; associate professor; efficiency; disruptive innovation; disruptive technologies; green chemistry; organic compound; mechanochemistry; mechanical energy; chemical reaction; milling jar; stainless steel; ball; funding; Natural Sciences and Engineering Research Council of Canada; National Natural Science Foundation of China.