High-Entropy Alloys

June 20, 2016

One of the first bits of

chemical knowledge that I learned as a

child was that

oil and

water don't

mix. This was also a common saying at that time that described a variety of

political and

social situations. Oil and water don't mix since water

molecules are

polar, and oil molecules are

non-polar. This results in oil being

hydrophobic. As a

young scientist, however, I was determined to find a process to mix oil and water.

I had among my tools a

vibratory wood saw. This was a

child's version of a

jigsaw built as a powerful

electric buzzer coupled to a jig saw blade. It was relatively

safe, since it would only cut thin pieces of soft wood, such as

balsa. I found that one of my

mother's tall

spice bottles could be inserted in place of the blade to form a vibratory mixer for

liquids.

I placed equal

volumes of

vegetable oil and water into the bottle and mixed them. At first, I thought that I had succeeded, but the mixture

separated after a time back to a layer of oil atop the water. This was my first lesson in

phase separation, a

thermodynamic phenomenon so critical to many chemical processes and the formation of

high strength alloys.

Any quantity of water can be mixed with itself, an

idea that seems trivial in its telling, but an idea that has deeper consequences. How far different can a substance be to still mix with water?

Heavy water (D2O) is somewhat different from H

2O, having a

density of 1.107 g/cc, about 10% greater than that of H

2O. Heavy water is completely

miscible in normal water.

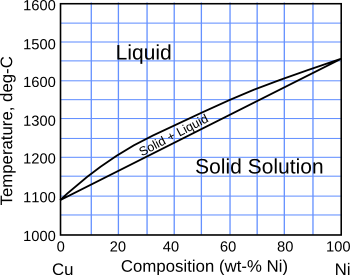

Extending ourselves further,

copper and

nickel are both

transition metals with the

face-centered cubic crystal structure. Nearly all

metals are

miscible in their liquid state, but copper and nickel are so similar that they are completely miscible in the

solid state, as can be seen in their

phase diagram.

The copper-nickel phase diagram.

(Created from available data using Inkscape.)

Atoms of two-component

solid solutions such as Cu-Ni are in a high

entropy state, since all the

crystal lattice sites of the

alloy are identical, and any one of the two components can reside at any lattice location. Consider the unusual and unlikely case in which nearly equal quantities of many component atoms form a solid solution. The

configurational entropy of such a multi-component alloy would be large; and, surprisingly, such

high entropy alloys exist.

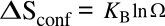

Boltzmann's entropy equation is

where

KB is

Boltzmann's constant of 1.38065 x 10

23 joule/

kelvin (J/K), and

Ω is the number of

states accessible to a system; that is, the ways in which the

atoms can be differently arranged. In the case of combining atoms of

i different elements of

mole fractions Xi, this equation becomes

where

R is the

gas constant of 8.314 J/K/

mol. For the special case of equal mixtures of components, we get the configurational entropy values as shown in the graph below.

Ideal configurational entropy for equi-atomic multicomponent alloys as a function of the number of components.

(Created with Gnumeric.)

As any

metallurgist knows, liquid mixtures of several different types of metal atoms will give you a solid consisting of multiple crystal types when cooled. This thermodynamic phenomenon has been used to advantage in the creation of high strength alloys, such as those used in

turbine engine blades. For example, MAR-M-247, a

Martin Marietta nickel-based

superalloy has the following composition (

mass-%):[1]

Additionally, a little

hafnium or

zirconium is also added. This alloy has a crystal matrix of the face-centered cubic structure of nickel containing

gamma-prime and carbide phases that provide its high temperature strength.

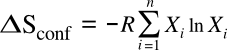

There was much head-scratching among metallurgists (especially the older,

balding ones) in 2004 when B. Cantor, I.T.H. Chang , P. Knight, and A.J.B. Vincent of the

Oxford University Department of Materials produced a single phase alloy of equal portions of five components.[2] This alloy was

Fe20Cr20Mn20Ni20Co20, which forms a face-centered cubic solid solution. This discovery marked the beginning of serious study on high-entropy alloys.

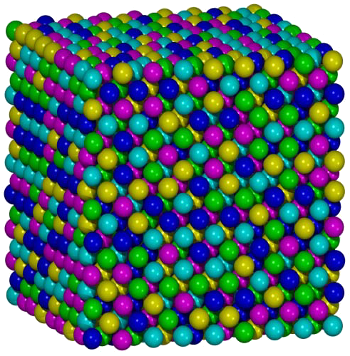

Atomic structure model of the Oxford University FeCrMnNiCo alloy.

In this image, magenta = Fe, green = Co, blue = Cr, cyan = Ni, and yellow = Mn. Aside from slight differences in atomic size, swapping colors would serve just as well, since the composition is equi-atomic.

(Image by Shaoqing Wang, via Wikimedia Commons.)

So, are there

properties of high-entropy alloys that are especially useful? One important application is their potential for use in

nuclear reactors.

Energetic particles such as

neutrons that impinge on an alloy will cause displacement of atoms from their positions in the crystal lattice. This generates

lattice defects and

dislocations that change the alloy's

mechanical properties. Equi-atomic multicomponent alloys have shown good resistance to such

radiation damage.

In an

open access paper in

Physical Review Letters,

scientists from the

University of Helsinki (Helsinki, Finland),

Oak Ridge National Laboratory (Oak Ridge, Tennessee), and the

University of Michigan (Ann Arbor, Michigan), report on

experiments and

modeling that show a substantial reduction of radiation damage in single-phase NiFe and NiCoCr alloys, as compared to

elemental Ni.[3-4]

They ascribe this effect to a reduction in dislocation mobility, with a result that dislocation structures grow more slowly. The radiation damage did not show any phase separation or

amorphization of the alloys.[3] In conventional alloys, a matrix element such as iron exists in greater concentration, and its radiation exposure is proportionately greater. In a high-entropy alloy, the dislodging

probability is distributed among all the

elements.

Scientists from the

Max-Planck-Institut für Eisenforschung (Düsseldorf, Germany) and the

Massachusetts Institute of Technology (Cambridge, Massachusetts) have reported in a recent issue of

Nature a way to transform a high-entropy alloy into a material that exhibits simultaneous

ductility and strength.[5-6]

In conventional alloys, you can have high ductility and low strength, or high strength and low ductility, while high-entropy alloys have high strength, but they're

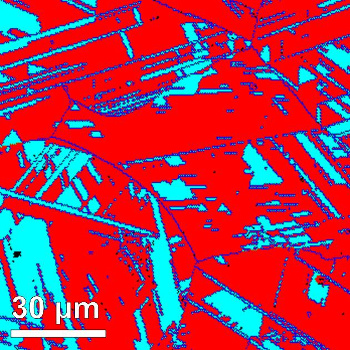

brittle and not ductile.[6] Their alloy, composed of 50% iron, 30% manganese, 10% cobalt and 10% chromium, has two coexisting crystal structures, and these

transform from one into the other, giving the desired mechanical properties. (see figure).[6]

Phases of the Fe50Mn30Co10Cr10 alloy, as imaged using electron backscatter diffraction.

(MPI f. Eisenforschung image, © 2016 Nature.)

![]()

References:

- W. Danesi, J. Hockin, and C. Lund, "Tungsten containing alloy," US Patent No. 3,759,707, September 18, 1973 (via Google Patents).

- B. Cantor, I.T.H. Chang, , P. Knight, and A.J.B. Vincent, "Microstructural development in equiatomic multicomponent alloys," Materials Science and Engineering, vols. 375-377 (July 2004), pp. 213-218, doi:10.1016/j.msea.2003.10.257.

- F. Granberg, K. Nordlund, M. W. Ullah, K. Jin, C. Lu, H. Bei, L. M. Wang, F. Djurabekova, W. J. Weber, and Y. Zhang, "Mechanism of radiation damage reduction in equiatomic multicomponent single phase alloys, Physical Review Letters, vol. 116, no. 13 (April 1, 2016), Document No. 135504. This is an open access paper with a PDF file available here.

- Akshat Rathi, "A new kind of metal could make nuclear reactors stronger and last longer," Quartz, March 21, 2016.

- Zhiming Li, Konda Gokuldoss Pradeep, Yun Deng, Dierk Raabe, and Cemal Cem Tasan, "Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off," Nature (May 18, 2016), doi:10.1038/nature17981.

- Strength and ductility for alloys, Max-Planck-Gesellschaft Press Release, May 24, 2016.

Permanent Link to this article

Linked Keywords: Chemistry; chemical; child; oil; water; mixture; mix; politics; political; society; social; molecule; chemical polarity; polar; non-polar; hydrophobe; hydrophobic; youth; young; scientist; vibration; vibratory; wood; saw; child; jigsaw; electric buzzer; safety; safe; ochroma; balsa; mother; spice; bottle; liquid; volume; vegetable oil; separate; phase; thermodynamic; strength of materials; high strength; alloy; idea; Heavy water (D2O); density; miscibility; miscible; copper; nickel; transition metal; face-centered cubic; crystal structure; metal; solid; phase diagram; Inkscape; solid solution; entropy; crystal lattice; alloy; configurational entropy; high entropy alloy; Boltzmann's entropy equation; Boltzmann's constant; joule; kelvin; microstate; state; atom; mole fractions; gas constant; mole; mol; Gnumeric; metallurgy; metallurgist; turbine engine blades; Martin Marietta; superalloy; mass; tantalum; tungsten; titanium; cobalt; molybdenum; chromium; iron; aluminum; boron; hafnium; zirconium; gamma-prime and carbide phases; hair loss; bald; Oxford University; Department of Materials; space-filling model; Atomic structure model; atomic radius; atomic size; Wikimedia Commons; materials properties; nuclear reactor; energy; energetic; subatomic particle; neutron; crystallographic defect; lattice defect; dislocation; mechanical properties; radiation damage; open access paper; Physical Review Letters; University of Helsinki (Helsinki, Finland); Oak Ridge National Laboratory (Oak Ridge, Tennessee); University of Michigan (Ann Arbor, Michigan); experiment; computer simulation; modeling; chemical element; elemental; amorphous solid; amorphization; probability; Max-Planck-Institut für Eisenforschung (Düsseldorf, Germany); Massachusetts Institute of Technology (Cambridge, Massachusetts); Nature; ductility; brittle; phase transition; transform; electron backscatter diffraction; W. Danesi, J. Hockin, and C. Lund, "Tungsten containing alloy," US Patent No. 3,759,707, September 18, 1973.