Friction and Superlubricity

July 2, 2015

Friction is one

physical principle that's important to the

common man for the simple reason that it costs him

money. When you sum all losses due to friction, such as increased

fuel use and

component replacement, there are estimates that friction accounts for losses equivalent to up to 10% of the US

gross domestic product.[1] I wrote about friction in several previous articles (

Tribology, April 27, 2015,

Van der Waals Friction, August 12, 2013, and

Friction, February 1, 2012).

We invest a lot of money in

lubricants and

lubricious coatings, such as

Teflon, but the best money spent is that on

research into how friction arises at the

atomic level. Knowledge of that can lead to

innovations in friction reduction. Friction is such an important

phenomenon that it captured the attention of

Leonardo da Vinci (1452-1519), who discovered that friction is a function of

load, only, and not a function of

contact area.

Guillaume Amontons (1663-1705) restated da Vinci's results, and he

theorized that friction arose form the

work needed to lift an object over

surface roughness.[3] After the discovery of the atomic nature of

matter, subsequent

conjectures on the fundamental processes for friction needed to await advances in

technology and

instrumentation, such as those that enabled recent

research at the

Massachusetts Institute of Technology (Cambridge, Massachusetts) just reported in

Science.[2-5]

A team of

physicists at MIT has performed an interesting

experiment in which they were able to adjust the difference in atomic spacing between two rubbing surfaces and measure their friction. Their

model system had one surface composed of up to six

ions moving across another "surface" simulated by an

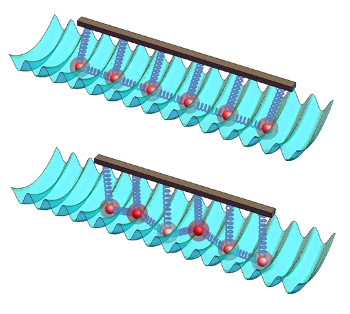

optical lattice (see figure).

Atoms are represented as balls on springs in this representation of ions sliding along the corrugations of an optical lattice.

In the top case, the periodicity of the ions and the lattice are the same. In the lower case, they're different.

(Still Images from a YouTube video.)[5)]

When atomically smooth surfaces are involved, friction usually occurs by a

stick-slip process.[2] Friction is important at the

nanoscale, where greater frictional forces are involved that can destroy small, moving mechanisms much faster than their larger counterparts. Says

Vladan Vuletic, a

professor in the

MIT Physics Department,

"There's a big effort to understand friction and control it, because it's one of the limiting factors for nanomachines, but there has been relatively little progress in actually controlling friction at any scale... What is new in our system is, for the first time on the atomic scale, we can see this transition from friction to superlubricity.[4]

A principal part of the MIT experiments is an optical lattice. This is an

egg carton shaped region of

electric potential creating by

interfering two

laser beams traveling in opposite directions. Their

electric fields form a

sinusoidal pattern in one

dimension.[4] Atoms traveling across an optical lattice are drawn to regions of minimum

potential, so the arrangement is an

analog to having an object move on an irregular surface.[4] In the experiments, from one to six ions could be moved across the optical lattice.[3]

While the optical lattice acts as one surface in the friction couple, the other is an ion

crystal comprised of

ionized ytterbium atoms. These atoms, sourced from a

small heated oven, are ionized by one laser, and then cooled to near

absolute zero by another. They're then trapped on a

metallic surface where their charges cause a

Coulombic repulsion that keeps them arrayed into a

lattice on the metal surface.[2,4]

The lasers allowed the research team to stretch and squeeze the ion crystal and push and pull it across the trapped ytterbium atoms.[4] Maximum friction, in a slip-stick fashion, was found when the period of the optical lattice matched that of the ytterbium ion array.[2,4] Says Vuletic, "It's like an

earthquake... There's force building up, and then there's suddenly a

catastrophic release of

energy."[4]

When the optical lattice period is mismatched to the atom spacing, friction between the two surfaces vanishes. At that point, stick-slip vanishes, the atoms can move fluidly across the optical lattice, and "

superlubricity" is achieved.[4] In this arrangement, some atoms are in troughs of the electric potential, others are at its peaks, and still others are somewhere in between. When the atom array is pulled across, the sliding of one atom down a peak relieves some

stress, and this allows another atom to climb out of a trough.[4]

The MIT research was funded by the

National Science Foundation and the

National Sciences and Engineering Research Council of Canada.[4]

In more

conventional friction research, scientists from the

Jülich Research Center (Jülich, Germany), the

Hankook Tire Co. LTD.(Daejeon, South Korea) and

Multiscale Consulting (Jülich, Germany) have been investigating the

molecular scale mechanisms responsible for

rubber friction for

tire tread compounds on

asphalt road surfaces.[6-7] They used measurements of road surface

topographies by

atomic force microscopy and conventional

stylus instruments, and they measured the friction at different

temperatures and sliding

speeds.[6] The stylus measurements were limited to a speed less than a

meter per second to avoid

heating from friction.[6]

While road

asperities, the rough points of the road, cause

viscoelastic deformations of the rubber surface that lead to friction, the research team found that

mechanical shear, when rubber is dragged

parallel to the road surface, is also a factor.[5] It appears that the shear friction arises from

bonding-stretching-

debonding cycles in the rubber molecules as they repeatedly stick to the road, stretch, and then release.[6]

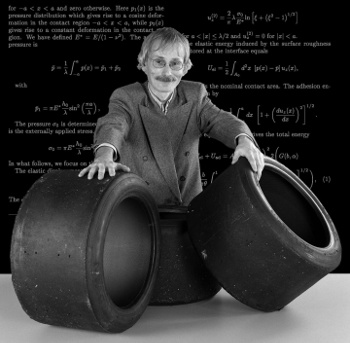

Bo Persson, a scientist at the Jülich Research Center in Germany, developed a

model of rubber friction that incorporated the viscoelasticity of the particular rubber compound and this shear effect. The

published experiments show a good

fit to Persson's

theory, which shows that temperature and speed are important

parameters.[6]

Says Bo Persson of the Jülich Research Center (Jülich, Germany), who has studied friction for twenty years, "Rubber friction is an extremely interesting topic and of extreme practical importance, for tires and very many other applications."[6]

(FZ Jülich photograph.)[6)]

These results, however, only apply to clean,

dry surfaces.

Wet surfaces would prevent the binding of the rubber molecules to the asphalt, so the shear contribution to friction is absent. In that case, a simplified model based on just viscoelasticity will give good results.[6]

References:

- Kenneth G. Budinski, "Friction, Wear, and Erosion Atlas," CRC Press, November 6, 2013, 309 pp. (via Google Books).

- Alexei Bylinskii, Dorian Gangloff, and Vladan Vuletić, "Tuning friction atom-by-atom in an ion-crystal simulator," Science, vol. 348, no. 6239 (June 5, 2015), pp. 1115-1118, DOI: 10.1126/science.1261422.

- Ernst Meyer, "Perspective, Physics - Controlling friction atom by atom," Science, vol. 348, no. 6239 (June 5, 2015), p. 1089, DOI: 10.1126/science.aab3539.

- Jennifer Chu, "Vanishing friction," MIT Press Release, June 4, 2015.

- Vanishing friction, Massachusetts Institute of Technology YouTube Video (Video produced and edited by Melanie Gonick, computer simulations courtesy of Alexei Bylinkskii), June 4, 2015.

- B. Lorenz, Y. R. Oh, S. K. Nam, S. H. Jeon, and B. N. J. Persson, "Rubber friction on road surfaces: Experiment and theory for low sliding speeds, "J. Chem. Phys., vol. 142, no. 19 (May 21, 2015), Document No. 194701, http://dx.doi.org/10.1063/1.4919221. A free PDF download of this paper is available at the link.

- Where the rubber meets the road, American Institute of Physics Press Release, May 15, 2015.

Permanent Link to this article

Linked Keywords: Friction; physical law; physical principle; commoner; common man; money; fuel; spare part; component replacement; gross domestic product; lubricant; non-stick surface; lubricious coating; polytetrafluoroethylene; Teflon; research; atom; atomic; innovation; phenomenon; Leonardo da Vinci (1452-1519); load; contact area; Guillaume Amontons (1663-1705); theory; theorize; work; surface roughness; matter; conjecture; technology; scientific instrument; instrumentation; research; Massachusetts Institute of Technology (Cambridge, Massachusetts); Science; physicist; experiment; scientific model; model system; ion; optical lattice; ball; spring; corrugated; corrugations; optical lattice; periodic function; periodicity; YouTube video; stick-slip process; nanoscopic scale; nanoscale; Vladan Vuletic; professor; MIT Physics Department; superlubricity; egg carton; electric potential; interference; wave propagation; interfering; laser; beam; electric field; sine wave; sinusoidal pattern; dimension; electric potential; analogy; analog; crystal; ionization; ionize; ytterbium; Knudsen Cell; small heated oven; absolute zero; metal; metallic; electrostatics; Coulombic repulsion; lattice; earthquake; catastrophe theory; catastrophic release; energy; stress; National Science Foundation; National Sciences and Engineering Research Council of Canada; convention; conventional; Jülich Research Center (Jülich, Germany); Hankook Tire Co. LTD.(Daejeon, South Korea); Multiscale Consulting (Jülich, Germany); molecule; molecular scale; rubber; tire tread; hemical compound; asphalt; road; topography; atomic force microscopy; stylus; temperature; speed; meter per second; heat; heating; asperity; viscoelasticity; viscoelastic; deformation; hear stress; mechanical shear; parallel; chemical bond; bonding; debonding; Bo Persson; mathematical model; scientific literature; publish; curve fitting; fit; scientific theory; parameter; dry; wet.