Graphene Production

May 26, 2014

There are several ways to make

scrambled eggs. The method I prefer is when the eggs are

whipped in a

bowl before

cooking, the resulting cooked portion being a very uniform blend of

yoke and

white. Another method is when the cracked eggs are added to the hot

frying pan, where they are

mixed,

in situ, but not very well. Some people may prefer the later result, but I think that if you're going to mix something, you should do it well, or not at all.

Blending of

powders and other

granular materials is an important

industrial processes for everything from

foodstuffs to

pharmaceuticals. A common

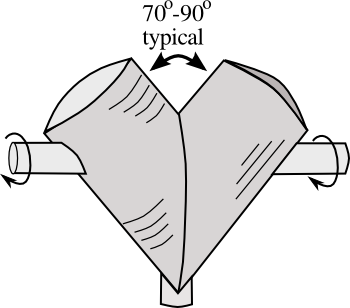

apparatus for doing such blending is the

double-cone "V" blender, as shown in the simplified

diagram, below.

Slow

rotation of the "V" shaped container shifts the contents from the

apex of the "V" to the two

prongs. At each rotation, the contents are divided in half, so the process is a lot like

shuffling cards. A large number of rotations ensures that the contents are well blended, just as a large number of shuffles will

randomize a

deck of cards. Blending time can be as long as fifteen

minutes.

Simplified diagram of a "V" blender.

(Illustration by the author using Inkscape.)

This

process looks good on paper, but there might be problems when mixing some

materials. The card shuffling

analogy assumes that all the cards are identical, and no cards stick together. Materials having different sized and shaped particles might be a problem, as would

static electricity, generated by the granules'

rubbing together, holding particles together.

The slow

mechanical action of a "V" blender contrasts sharply with the rapidly rotating

blades in a

kitchen blender. Early

electric motor technology was fairly primitive, so the first blenders required a heavy motor, which was mounted in a base. A

jar with the rotating blades at its bottom was inverted onto the motor. Modern blenders are smaller, handheld devices that can be immersed into most containers.

Kitchen blenders can be used to chop

solids, such as

bread crumbs and

coffee beans, but they're typically used for creating

purées or

liquid mixtures such as

pancake batter. Kitchen blenders, and their

industrial cousins, are often seen in

chemistry laboratories, since they are used there for similar non-food mixing tasks. A team of more than 25

scientists from

Ireland and the

UK has just

published its discovery that a laboratory blender can be used to

exfoliate graphene sheets from

graphite.[1-4]

The

research team of

chemists,

physicists and

materials scientists from

Trinity College Dublin (Dublin, Ireland),

Thomas Swan and Company Limited (Consett, UK),

STFC Daresbury Laboratories (Warrington, UK) and

Oxford University (Oxford, UK) subjected mixtures of graphite flake in liquid

solvents to the mixing action of a

Silverson Machines Ltd. LSM high

shear laboratory mixer in a demonstration of an industrially scalable process for production of large quantities of

defect-free graphene.[1-2]

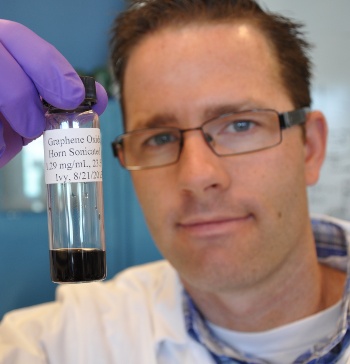

Caution advised.

Jacob Lanphere, a Ph.D. candidate at the The University of California, Riverside, holding a solution of graphene oxide.

A UCR study found that graphene oxide nanoparticles are very mobile in waterways, and they would have a negative environmental impact if released.

(University of California, Riverside, photograph.)

The 250

watt motor of the Silverson Machines mixer rotates a 50 mm mixing head at 6000

rev/min under load.[2] As

Count Rumford proved in his

cannon boring experiments, mechanical action such as this generates

heat. For that reason, the mixing vessel is placed in a

water bath at 15

°C.[2]

The team identified the processing

parameters under their control. These included mixing

time, mixing

speed, mixing

volume,

rotor diameter, graphite

concentration, rotor-

stator gap, rotor-stator

position in the liquid volume, the presence/number/configuration of baffles, graphite pre-treatment, graphite type, and solvent type.[2]

Solvents were selected based on their

surface energy (or

solubility parameter) close to that of graphene itself. This results in a low

mixing energy, which leads to stabilization of the exfoliated graphene flakes against reaggregation.[2]

organic solvents used in this study were

N-methyl-2-pyrrolidone and

N-cyclohexyl-2-pyrrolidone. Also suitable are

aqueous surfactant solutions, such as

sodium cholate in water, and some

polymer solutions.[2]

The research team demonstrated that high-shear mixing of graphite in such solvents results in

dispersions of exfoliated graphene

nanosheets in liquid volumes as small as a few hundred of

milliliters up to hundreds of

liters.[1,3] Exfoliation was found to occur when the local shear rate exceeds 10

4 s−1. These flakes were verified as

unoxidized and free of

basal-plane defects by

X-ray photoelectron spectroscopy and

Raman spectroscopy.[1]

Funding for this project was provided jointly by Thomas Swan Ltd. and the

Science Foundation Ireland.[3] Thomas Swan Ltd. has commercialized this discovery with two products, Elicarb® Graphene Powder and Elicarb® Graphene Dispersion.[3] This process can be applied to exfoliate

boron nitride,

molybdenum disulfide (MoS

2) and other layered crystals.[1]

After you place graphene on a

substrate, the next step would be its modification to produced

electronic devices such as

transistors. That's the topic of research published in a recent issue of

Nature Materials by scientists from the

University of Arizona (Tucson, Arizona), the

Massachusetts Institute of Technology (Cambridge, Massachusetts),

Harvard University (Cambridge, Massachusetts), the

US Army Research Laboratory (Adelphi, Maryland), the

National Institute for Materials Science (Tsukuba, Japan), and the

Instituto de Ciencia de Materiales de Madrid (ICMM-CSIC, Madrid, Spain).[5-6]

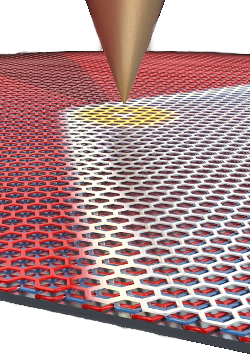

Working with something as small as graphene requires a special tool, and that's the

scanning tunneling microscope (STM), which is also used to image graphene surfaces. Although the

bonding within graphene sheets is very strong, the inter-sheet bonding is weak, so it's possible to slide one layer on another.

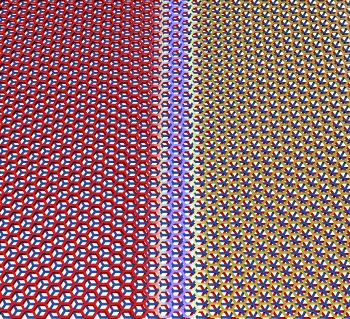

carbon atoms in three stacked graphene layers can arrange themselves in two different configurations,

Bernal and

rhombohedral. In the Bernal stacking, the carbon atoms of the top layer are directly above the atoms in the lower layer. In rhombohedral stacking, they're aligned with the holes in the bottom layer.[6]

Trilayers of graphene sheets can stack in two different configurations, which can co-exist in a single flake with a transition region in between.

(Pablo San-Jose ICMM-CSIC image, via University of Arizona.)

(Click for larger image)

These exhibit very different

electronic properties, the Bernal stacking leading to a

semiconductor, while the rhombohedral forms an

insulator.[5] Both stacking configurations can coexist on a single graphene flake, and the region between them, called a

domain wall, accommodates the

strain with a modified

carbon–carbon bond distance.[5-6] The research team found that the applied

electric field of a scanning tunneling microscopy tip can move this domain wall.[6]

Study

coauthor,

Brian LeRoy, an

associate professor in the

University of Arizona Department of Physics, explains that "It is extremely rare for a material to change its

crystal structure just by applying an electric field... Making trilayer graphene is an exceptionally unique system that could be utilized to create novel devices."[6]

The research team found that the

free energy difference between the two stacking states scales with the

second power of the electric field, so that the rhombohedral stacking is favored at higher electric fields.[5] They speculate that use of a wide, knife-edged

electrode, rather than the single point, might allow movement of a domain over larger areas.[6]

The metal tip of a scanning tunneling microscope can be used to move the domain border between different graphene configurations in the same flake.

Pablo San-Jose ICMM-CSIC image, via (University of Arizona.)

![]()

References:

- Keith R. Paton, Eswaraiah Varrla, Claudia Backes, Ronan J. Smith, Umar Khan, Arlene O'Neill, Conor Boland, Mustafa Lotya, Oana M. Istrate, Paul King, Tom Higgins, Sebastian Barwich, Peter May, Pawel Puczkarski, Iftikhar Ahmed, Matthias Moebius, Henrik Pettersson, Edmund Long, João Coelho, Sean E. O'Brien, Eva K. McGuire, Beatriz Mendoza Sanchez, Georg S. Duesberg, Niall McEvoy, Timothy J. Pennycook, et al., "Scalable production of large quantities of defect-free few-layer graphene by shear exfoliation in liquids," Nature Materials, April 20, 2014, doi:10.1038/nmat3944.

- Supplementary Information for ref. 1.

- AMBER in world-first Graphene Innovation, Centre for Research on Adaptive Nanostructures and Nanodevices Press Release, April 22, 2014.

- Rachel Courtland, "Graphene You Can Whip Up In A Blender," IEEE Spectrum, April 21, 2014.

- Matthew Yankowitz, Joel I-Jan Wang, A. Glen Birdwell, Yu-An Chen, K. Watanabe, T. Taniguchi, Philippe Jacquod, Pablo San-Jose, Pablo Jarillo-Herrero andBrian J. LeRoy, "Electric field control of soliton motion and stacking in trilayer graphene," Nature Materials, advance online publication, April 28, 2014, doi:10.1038/nmat3965.

- Daniel Stolte, "Playing Pool with Carbon Atoms," University of Arizona Press Release, April 30, 2014.

Permanent Link to this article

Linked Keywords: Scrambled eggs; whisk; whipped; bowl; cooking; egg yolk; egg white; frying pan; mixing; blending; powder; granular material; industrial process; foodstuffs; pharmaceuticals; apparatus; industrial mixer">double-cone "V" blender; diagram; rotation; apex; prong; shuffling cards; randomization; randomize; playing card; deck of cards; minute; Inkscape; batch production; process; looks good on paper; material; analogy; static electricity; rubbing; mechanics; mechanical; blade; kitchen; blender; electric motor; electronics technology; jar; solid; bread crumb; coffee bean; purée; liquid; mixtures; pancake; batter; industry; industrial; chemistry; laboratory; scientist; Ireland; United Kingdom; UK; scientific literature; publish; exfoliation; exfoliate; graphene; graphite; research; chemist; physicist; materials scientist; Trinity College Dublin (Dublin, Ireland); Thomas Swan and Company Limited (Consett, UK); STFC Daresbury Laboratories (Warrington, UK); Oxford University (Oxford, UK); solvent; Silverson Machines Ltd.; shear stress; crystallographic defect; Jacob Lanphere; Doctor of Philosophy; Ph.D.; The University of California, Riverside; graphite oxide; graphene oxide; nanoparticle; waterway; environmental impact; watt; revolutions per minute; rev/min; Benjamin Thompson; Count Rumford; cannon; boring; experiment; heat; water bath; celsius; °C; parameter; time; speed; volume; rotor; diameter; concentration; stator; position; surface energy; solubility parameter; entropy of mixing; mixing energy; organic; N-methyl-2-pyrrolidone; N-cyclohexyl-2-pyrrolidone; aqueous; surfactant; cholic acid; sodium cholate; polymer; dispersion; nanosheet; milliliter; liter; second; oxide; unoxidized; basal-plane; X-ray photoelectron spectroscopy; Raman spectroscopy; Science Foundation Ireland; boron nitride; molybdenum disulfide; substrate; electronic device; transistor; Nature Materials; University of Arizona (Tucson, Arizona); Massachusetts Institute of Technology (Cambridge, Massachusetts); Harvard University (Cambridge, Massachusetts); United States Army Research Laboratory (Adelphi, Maryland); National Institute for Materials Science (Tsukuba, Japan); Instituto de Ciencia de Materiales de Madrid (ICMM-CSIC, Madrid, Spain); scanning tunneling microscope; chemical bond; bonding; carbon; atom; Bernal; rhombohedral; Pablo San-Jose ICMM-CSIC; electronic properties; semiconductor; insulator; domain wall; strain; carbon–carbon bond; electric field; coauthor; Brian LeRoy; associate professor; University of Arizona Department of Physics; crystal structure; gibbs free energy; quadratic equation; second power; electrode.