Energy Harvesting Cantilevers

January 14, 2013

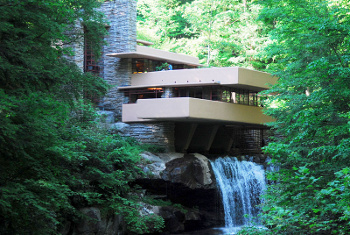

The

cantilever is one of the more interesting

mechanical objects, and one of its most interesting examples is

Fallingwater, designed by

architect,

Frank Lloyd Wright (see photograph). It takes a good knowledge of

material properties and

mechanics to attempt a structure such as this.

Frank Lloyd Wright's Fallingwater

This house was built for the Pittsburgh department store magnate, Edgar J. Kaufmann, whose store my wife and I used to frequent while I was a post-doc at the University of Pittsburgh.

(Via Wikimedia Commons))

Fallingwater, located at

39° 54' 24.0" N, 79° 28' 5.0" W, is on the

United States National Register of Historic Places (

Reference number 74001781). Architects have a good knowledge of mechanical engineering principles, but in the days before

computer modeling, it was easy to make mistakes.

Wright specified too few

iron reinforcement bars (rebars) in the

concrete cantilevers; so much so, that it's reported that the

building contractor added more, since he had practical experience in such matters. That notwithstanding,

cracks developed, and a 1990s study showed that the main cantilever (the lower level in the photograph) had

deflected seven

inches.[1]

In

energy harvesting applications, cantilever deflection is a good thing. I once developed a

vibration energy-harvesting device in which the natural resonance of a

piezoelectric coated cantilever beam produced a small amount of

electrical power (about 10

milliwatt). Vibration energy harvesting works well if the vibration comes from a machine with a fixed vibration frequency, such as a constant speed motorized device. In such cases, the resonant frequency of the cantilever can be matched to the vibration

frequency for maximum

energy transfer.

For a cantilever clamped at one end, as shown in the figure, the

resonant frequency f is given as

f = (3.516/2π)(t/√12)(1/L2)(E/ρ)1/2

where

t is the beam thickness,

L is the beam length,

E is

Young's modulus, and

ρ is the material

density. Surprisingly, the width of the beam doesn't figure into the formula.

Here's a spreadsheet for your own calculations of cantilever resonance frequency.

A cantilever beam.

(Illustration by the author, rendered using Inkscape.)

I reviewed a cantilever-type vibration energy harvester that uses an

electret instead of a piezoelectric in a

previous article (Electret Energy Harvester, December 7, 2011). This device, as shown in the figure, was investigated by

scientists from the

Laboratoire d'électronique des technologies de l'information (CEA-Leti, Grenoble, France) and

Centre national de la recherche scientifique (CNRS).[2-4] This cantilever has a

proof mass at its tip, so its different

moment of inertia leads to a lower frequency than the equation above.

A cantilever beam vibration energy-harvester using an electret material. (Via arXiv Preprint Server, Ref. 4, Fig. 1.)[4)]

Just as in an

electret microphone, vibration in the counter

electrode generates a

voltage. Movement of the cantilever causes a change in the

capacitance, which puts a voltage across the load

resistance, as described by the following equation:

∂V/∂t = Q / (∂C/∂t)

in which

Q is the surface charge carried on the electret. A prototype harvester using a

silicon cantilever and a

Teflon (PTFE) electret gave 17 microwatts into a 210

megohm load for 0.2 g vibration.[4]

In a

previous article, (Cantilever Energy Harvesting, August 16, 2011) I described two energy-harvesting devices based on the cantilever. One of these uses

beta decay, which is the emission of high-energy

electrons when

neutrons decay into

protons.

A cantilever beam can be

charged by the electrons from a nearby beta radiator, such as

nickel-63. Because of

charge conservation, the nickel metal develops an equal and opposite charge, so the cantilever beam is attracted to it, as shown in the figure. When the beam touches the beta source, the charges are neutralized, and the cantilever beam springs back to its original state. The energy from bending, principally from the rapid snap-back after charge neutralization, can be converted to a voltage by a

piezoelectric material.

A beta-radiation energy harvester (left), and a cantilever pyroelectric energy-harvester (right). (Illustration by the author, rendered using Inkscape.)

Cantilever beta radiation energy harvesters have been produced with 7%

efficiency; and, since nickel-63 has a

half-life of more than 100 years, long-lived power sources can be made. Beta particles are easier to

shield than other forms of radiation, so these devices would not be particularly dangerous.[5-6]

Oak Ridge National Laboratory has invented a cantilever device to harvest energy from

waste heat (see figure).[7-8] The cantilever in this case is a

bimetallic strip like those used in some

thermostats. The differential

thermal expansion of the dissimilar metals will cause the beam to bend.

When the cantilever is in contact with a hot surface,

thermal conductivity causes the bimetallic strip to bend and contact the cold surface. Cooling of the strip at the cold surface causes the cycle to repeat. Since the cycling is at a low rate, piezoelectrics would not be a suitable means of converting mechanical energy to electricity. Instead, a

pyroelectric material is used, and the pyroelectric generates electricity through the hot-cold cycling.

The ORNL devices are

MEMS structures about a

millimeter square. One principal advantage of this device is that electrical power can be generated at a temperature differential of just a few degrees, such as that between a

human and

room temperature.

Recently, the

French team responsible for the cantilever electret vibration energy harvester has published the design of a thermal energy harvester that, like the ORNL device, uses a bimetal element. In their case, however, the energy conversion is by the electret principle used in their previous device, and the bimetallic strip is anchored at both ends, as shown in the figure.[9] Since the strip is not anchored at a single end, it does not qualify as a cantilever, but the device structure is similar.

A thermal gradient energy-harvester using an electret energy converter. (Fig. 3c of ref. 9, via the arXiv Preprint Server.)[9)]

The electret elements, which are built on both an upper and lower surface, are 100 nm-thick

corona-charged parylene layers on 2μm-thick

SiO2 layers on

silicon. The bimetal strip is 115 μm thick, 30 mm long and 10 mm wide, coated also with parylene, and it's formed from a high thermal expansion material (B72M,

Mn-

Cu18%-

Ni10%) joined to

Invar. The strip was designed to snap in one direction at 47°

C, and the other at 42.5°C. The entire device is 33 mm wide and about 2 mm high.[9]

The bimetal strip snaps about once per second, and each snap produces a pulse of hundreds of volts into a high impedance, 10

9 ohm load. There's 341 μW peak at each pulse, but the pulse width is narrow, so the average power is lower. Experimentally, there was a 5.5 μW average power output for a 50°C temperature gradient.

References:

- Background on Fallingwater's Structure, Western Pennsylvania Conservancy, fallingwater.org.

- S Boisseau, G Despesse, T Ricart, E Defay and A Sylvestre, "Cantilever-based electret energy harvesters," Smart Materials and Structures, vol. 20 no. 10 (October, 2011), Document No. 105013.

- S. Boisseau, G. Despesse, T. Ricart, E. Defay and A. Sylvestre, "Cantilever-based electret energy harvesters," arXiv Preprint Server, November 10, 2011.

- S. Boisseau, G. Despesse and A. Sylvestre, "Electret-based cantilever energy harvester: design and optimization," arXiv Preprint Server, November 10, 2011.

- Bill Steele, "Tiny atomic battery developed at Cornell could run for decades unattended, powering sensors or machines," Cornell University Press Release, October 16, 2002.

- Mark Paulson, "Nano-Nuclear Batteries".

- Ron Walli, "ORNL energy harvesters transform waste into electricity," DOE/Oak Ridge National Laboratory Press Release, May 16, 2011.

- MEMS-Based Pyroelectric Thermal Energy Scavenger, Oak Ridge National Laboratory, October 1, 2010.

- S. Boisseau, G. Despesse, S. Monfray, O. Puscasu and T. Skotnicki, "A bimetal and electret-based converter for thermal energy harvesting," arXiv Preprint Server, December 4, 2012.

Permanent Link to this article

Linked Keywords: antilever; mechanical; Fallingwater; architect; Frank Lloyd Wright; material properties; mechanics; Edgar J. Kaufmann; Kaufmann's Department Store; postdoctoral research; post-doc; University of Pittsburgh; 39° 54' 24.0" N, 79° 28' 5.0" W; >United States National Register of Historic Places; Reference number 74001781; computer simulation; computer modeling; iron reinforcement bar; rebar; concrete; general contractor; building contractor; fracture; crack; deflection; inch; energy harvesting; vibration; piezoelectricity; piezoelectric; electrical power; milliwatt; frequency; energy; resonant frequency; Young's modulus; density; cantilever resonance.xls; spreadsheet; Inkscape; electret; scientist; Laboratoire d'électronique des technologies de l'information; Centre national de la recherche scientifique; proof mass; moment of inertia; arXiv Preprint Server; electret microphone; electrode; voltage; capacitance; resistance; silicon; polytetrafluoroethylene; Teflon; megohm; beta decay; electron; neutron; proton; electric charge; nickel-63; charge conservation; >piezoelectric; energy conversion efficiency; half-life; radiation protection; shield; Oak Ridge National Laboratory; waste heat; bimetallic strip; thermostat; thermal expansion; thermal conductivity; pyroelectric; microelectromechanical system; MEMS; millimeter; human; room temperature; France; French; corona discharge; corona-charged; parylene; silicon dioxide; SiO2; silicon; manganese; Mn; copper; Cu; nickel; Ni; Invar; Celsius; C.