Making Diamonds

December 16, 2013

Contrary to advertising claims,

diamonds are not forever. Diamond will burn, just like its

chemical cousin,

charcoal, if

combustion is initiated. The combustion

product is

carbon dioxide.

Thermodynamics confirms this

observation, since the

free energy of the combustion

reaction at

standard temperature and pressure (298.15

K and 1

atmosphere) is negative;[1] viz.,

C(Diamond) + O2(gas) -> CO2(gas)

ΔGf(Diamond) = 0.693 kcal/mole

ΔGf(Oxygen) = 0 kcal/mole

ΔGf(Carbon Dioxide) = -94.258 kcal/mole

ΔG(Reaction) = -94.951 kcal/mole

Although the reaction is highly favored at

room temperature, this combustion reaction has an

activation energy that must be overcome before it happens. As a consequence, diamond

will only ignite at a

temperature of 850-1,000°C in air, or 720-800°C in pure oxygen.

The combustion of diamond to form carbon dioxide was

experimentally confirmed by

Antoine Lavoisier in 1772. Lavoisier concentrated the

Sun's rays with a

lens to heat a diamond in an oxygen atmosphere to produce carbon dioxide. Later, the

chemist,

Smithson Tennant, showed that the combustion of

graphite produced the same result, confirming that diamond and graphite are

allotropic forms of

carbon.

The carbon phase diagram.

The triple point (TP) is around 4600 K and 10.8 MPa.

(Wikimedia Commons image, from data in ref. 2, modified using Inkscape.)[2)]

As the carbon phase diagram shows, the diamond phase of carbon exists only at high temperatures and high pressures. Such conditions occur at depths about a hundred

miles within

Earth's mantle, and natural diamonds have grown there over the course of

billions of years. They're available at Earth's surface only though transport of

magma in

volcanic eruptions, and they occur in the

igneous rocks,

kimberlite and

lamproite.

The

French chemist,

Henri Moissan, who won the 1906

Nobel Prize in Chemistry for his

research on

fluorine, thought he had discovered a simple process to mimic the temperature and pressure conditions necessary for diamond formation. Carbon dissolves in

iron, and that's how we get

steel.

Moissan saturated iron with carbon at about 3500°

C, and then

quenched the

metal in cold

water. He hoped that the

compressive forces of

solidification would transform the carbon into diamond, and he did find diamond-like

crystals in the product.

Sir Charles Parsons, an

Anglo-Irish engineer and

inventor of the

steam turbine, tried to

reproduce Moissan's results, but he wasn't able to make diamonds. It's possible that Moissan had actually produced crystals of

magnetite (Fe

3O

4).[3]

High pressure

technology advanced considerably in the

20th century, mostly though the efforts of

American physicist,

Percy Bridgman (1882-1961). Bridgeman won the 1946

Nobel Prize in Physics for his high pressure research. It had finally become possible to do a brute-force

synthesis of diamond through application of the proper temperatures and pressures.

Tracy Hall, a

physical chemist working at the

General Electric Research Laboratory in

Schenectady, New York, advanced Moissan's carbon-in-iron process by doing it in a high temperature

press. Hall's

apparatus, which first produced diamonds on December 16, 1954, could reach 2000°C and 10

GPa.[3] Small (0.15

millimeter) diamonds, useful for

industrial purposes, were produced not only from graphite mixed with iron, but mixed also with

nickel and from

iron sulfide.[4-5] Hall's reward for changing the world was apparently a $10

US savings bond (purchase value, $5.00).[6]

The crystal structure of diamond is cubic, with each carbon atom joined to others by a 154 picometer bond.

(Wikimedia Commons image, modified using Inkscape.)

This high temperature-high pressure condition is required when you're changing graphite to diamond, but

materials scientists wondered whether the diamond crystal structure might be built atom-by-atom from the

decomposition of

organic chemicals.

The simplest of these is

methane (CH

4), which is mixed in small quantities with

hydrogen gas and excited into a

plasma at low pressures. The gas atoms have a separate identity in the plasma, and some of the carbon atoms will form diamond on a

substrate. The purpose of the excess hydrogen is to strip away carbon not bonded into diamond.

This

chemical vapor deposition (CVD) process produces

polycrystalline diamond at a very low growth rate, since the reaction is limited by the available quantity of carbon in the plasma. However,

thin films of diamond are useful for a variety of applications, from

scratch-resistant eyeglasses to

low wear mechanical components.

One company has developed a method to make larger, single crystal diamond by a similar process.

Since diamond has unique material properties, such as high

thermal conductivity and extreme

hardness, there's still ongoing research into methods of diamond production.

Chemical engineers at

Case Western Reserve University (Cleveland, Ohio) have teamed with

physicists at

Michigan Technological University (Houghton, Michigan) to develop a process for making

nanoscale diamonds (nanodiamonds). Their CVD process is unlike other such processes, since it produces a nanodiamond

powder in a gas-phase reaction without a substrate.[7-8]

These nanodiamonds of 2-5

nanometer size are produced in a reaction of

ethanol (CH

3CH

2OH) and hydrogen at

atmospheric pressure and a (non-plasma) temperature of less than a hundred degrees

Celsius. Assistance in plasma creation came from an

argon carrier gas.[8] The nanodiamonds are true diamonds with

diamond cubic,

n-diamond and

lonsdaleite crystal structure.[7] Interestingly, lonsdaleite, an

hexagonal form of diamond, is rare on Earth but found in

meteorites, so the

cosmos has been making nanodiamonds for

eons.[7-8]

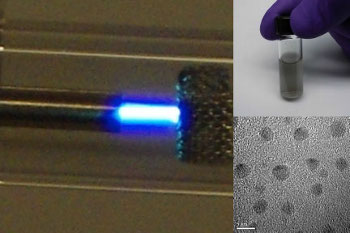

Nanodiamond synthesis at Case Western Reserve University.

Bright blue plasma is shown at the left, producing nanodiamonds at bottom.

(Case Western Reserve University images.[7]

Says

Mohan Sankaran, an

associate professor of

chemical engineering at Case Western Reserve and the leader of the project,

"This is not a complex process: ethanol vapor at room temperature and pressure is converted to diamond... We flow the gas through a plasma, add hydrogen and out come diamond nanoparticles. We can put this together and make them in almost any lab."[8]

One helpful factor was the

surface energy of diamond. This makes the nanodiamonds more stable than graphite, since nanoparticles have a high

ratio of surface area to volume. This ensured that most

nucleated nanoparticles would be diamond, and the hydrogen removed any non-diamond particles.[8]

References:

- Free energy data from L. B. Pankratz, "Thermodynamic Properties of Elements and Oxides," U. S. Bureau of Mines Bulletin 672, U. S. Government Printing Office (1982).

- J.M. Zazula, "On Graphite Transformations at High Temperature and Pressure Induced by Absorption of the LHC Beam," LHC Project Note 78, CERN, January 18, 1997 (PDF File).

- Artificial Diamonds, Human Touch of Chemistry Web Site.

- Howard Tracy Hall, "Diamond synthesis," U.S. Patent No. 2,947,608, August 2, 1960 (via Google Patents).

- H. P. Bovenkerk, F. P. Bundy, H. T. Hall, H. M. Strong and R. H. Wentorf, Jr., "Preparation of Diamond," Nature, vol. 184 (October 10, 1959), pp. 1094-1098 (PDF reprint at Tracy Hall Web Site).

- Thomas H. Maugh II, "General Electric chemist invented process for making diamonds in lab - H. Tracy Hall, 1919 - 2008," Los Angeles Times, July 31, 2008.

- Ajay Kumar, Pin Ann Lin, Albert Xue, Boyi Hao, Yoke Khin Yap and R. Mohan Sankaran, "Formation of nanodiamonds at near-ambient conditions via microplasma dissociation of ethanol vapour," Nature Communications, vol. 4, article no. 2618 (October 21, 2013), doi:10.1038/ncomms3618.

- Researchers develop way to inexpensively create nanodiamonds in lab setting, Case Western Reserve University Daily, October 28, 2013.

Permanent Link to this article

Linked Keywords: Diamond; allotropes of carbon; charcoal; combustion; product; carbon dioxide; thermodynamics; observation; Gibbs free energy; chemical reaction; standard conditions for temperature and pressure; standard temperature and pressure; STP; kelvin; K; bar; atmosphere; kilocalorie per mole; kcal/mole; oxygen; carbon dioxide; room temperature; activation energy; material properties of diamond; temperature; experiment; Antoine Lavoisier; Sun; lens; chemist; Smithson Tennant; graphite; allotropic form; carbon; phase diagram; triple point; Wikimedia Commons; Inkscape; mile; Earth's mantle; geologic time scale; billions of years; magma; volcanic eruption; igneous rock; kimberlite; lamproite; France; French; chemist; Henri Moissan; Nobel Prize in Chemistry; research; fluorine; iron; steel; Celsius; C; quenching; quench; metal; water; compression; compressive forces; freezing; solidification; crystal; Sir Charles Parsons; Anglo-Irish; engineer; inventor; steam turbine; reproducibility; magnetite; technology; 20th century; United States; American; physicist; Percy Bridgman (1882-1961); Nobel Prize in Physics; synthesis; Tracy Hall; physical chemist; General Electric Research Laboratory; Schenectady, New York; press; apparatus; pascal; GPa; millimeter; industrial-grade diamond; nickel; pyrite; iron sulfide; US savings bond; diamond cubic; chemical bond; materials science; materials scientist; chemical decomposition; organic compound; organic chemical; methane; hydrogen gas; plasma; substrate; chemical vapor deposition; CVD; polycrystalline; thin film; scratch resistance; scratch-resistant; eyeglasses; tribology; low wear; mechanical component; Apollo Diamond; thermal conductivity; hardness; chemical engineer; Case Western Reserve University (Cleveland, Ohio); physicist; Michigan Technological University (Houghton, Michigan); nanoscopic scale; nanoscale; powder; nanometer; ethanol; atmospheric pressure; Celsius; argon; diamond cubic; n-diamond; lonsdaleite; hexagonal; meteorite; cosmos; aeon; eon; Mohan Sankaran; associate professor; chemical engineering; surface energy; ratio of surface area to volume; nucleation; nucleated; Howard Tracy Hall, "Diamond synthesis," U.S. Patent No. 2,947,608, August 2, 1960.