Pop-Up Robots

February 23, 2012

There was a joke in

engineering labs about a decade ago that the only product of

university research on

robotics was

video clips of

robots. Sure, those videos of robot

snakes slithering up stairways and through

pipes were impressive, but they all seemed like solutions waiting for a problem.

The useful robots were never those cute mechanisms seen in the

Sunday supplement, or on

Internet videos. They were the huge

welding machines for

automobiles that rhythmically moved as if dancing to

Swan Lake; or, perhaps,

The Rite of Spring, when there were

mechanical problems.

Times have changed, as robots have become minuscule, and airborne, and the world has evolved into a more dangerous place. Many government organizations are hoping to procure the proverbial "

fly-on-the-wall" for

surveillance.

As a long time member of the

Electronic Frontier Foundation, I oppose

unwarranted government surveillance of its citizens. However, small, non-lethal, devices such as these can be important in protecting

combat troops through

intelligence-gathering. The

maxim,

knowledge is power, is especially true in wartime.

Bletchley Park and the

Manhattan Project are prime examples example of that.

One impressive display of flying robot prowess was demonstrated recently by

engineers at the

University of Pennsylvania's General Robotics, Automation, Sensing and Perception (GRASP) Laboratory. The laboratory has been developing

helicopter objects, about the size of a human hand, called "nano quadrotors."[1] The "quad" appellation comes from their having four rotors, which makes

acrobatics much easier than for other types of flying objects, but the nano doesn't refer to

nanotechnology, since these are much larger.

A

YouTube video shows a

swarm of up to twenty of these nano quadrotors doing

synchronized flying. At this point, I don't think that position sensing is indigenous to these robots. I think that some room equipment helps with that. However, at the rate that

electronics is shrinking, a small

GPS unit is not too far in the future.

Power, however, will always be a problem.

When such robots do shrink to extremely small sizes, traditional

manufacturing techniques will become difficult. Furthermore, when you have many such robots,

transportation will also become an issue. If you want to drop thousands from a

drone aircraft, even if they're lightweight, where would you find the volume? Engineers at

Harvard University's School of Engineering and Applied Sciences, assisted by

KMel Robotics, have been developing a technique that would solve both problems.[3]

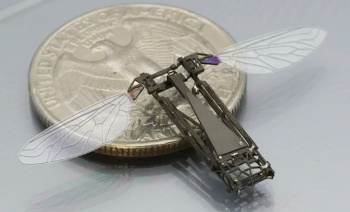

The Harvard Mobee is just 2.4 millimeters tall.

Sixty-three Mobees have the mass of a US quarter.

(Screen capture from a YouTube video))

The Harvard efforts have been centered around manufacture of their particular flying machine, a

coin-sized,

bee-inspired machine (see figure). Their current device is called the "Mobee," for

monolithic bee, is assembled by "popping-up" in a

scaffold to unfurl and interlock its more than twenty

origami-type folds. Their current version has eighteen

laser-cut laminated sheets of

carbon fiber,

Kapton (for

hinges, as shown in the figure below), and miscellaneous sheets of

titanium,

brass,

ceramic, and

adhesive.[3]

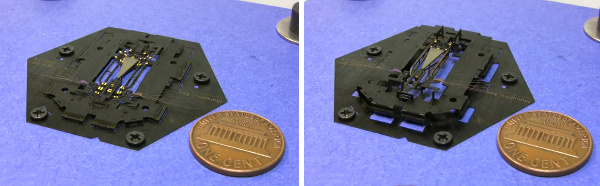

Making a micro hinge.

Kapton is used as the hinge layer in the Harvard Mobee.

(Screen capture from a YouTube video))

The Harvard Mobee work is led by

Associate Professor of

Electrical Engineering,

Robert J. Wood, who is also a member of the

Wyss Institute for Biologically Inspired Engineering at Harvard. Team members include

doctoral candidates, Pratheev Sreetharan and J. Peter Whitney.[3]

Says Wood,

"Our new techniques allow us to use any material including polymers, metals, ceramics, and composites... The ability to incorporate any type and number of material layers, along with integrated electronics, means that we can generate full systems in any three-dimensional shape."[3]

Here's a short summary of the Mobee specifications

• Folding joints = 22

• Assembly scaffold folding joints = 115

• Total device folding joints = 137

• Number of brass pads for "glue" points = 52

• Total number of "glue" points = 24

• Mass = 90 mg

Pop goes the micro-robot! The left image is the laminated, non-deployed state. The right image is the popped-up Mobee. A base plate sets the alignment of the parts, which is better than five micrometers. A 100% yield is currently realized.[3] (Screen captures from a YouTube video))

Aside from the obvious advantage that a

planar process is used to create

three-dimensional structures, many such objects can be processed simultaneously on a single sheet. The process, for which a

patent has been applied, is not limited to creation of the Mobee, but it can be used for fabrication of many other types of devices.[3]

This process will be described in the March issue of the

Journal of Micromechanics and Microengineering, whose authors will also include

graduate student, Kevin Ma, and

research assistant, Marc Strauss. External funding for this research was provided to Harvard by the

U.S. Army Research Laboratory and the

National Science Foundation.[3]

References:

- Evan Ackerman, "Swarming Quadrotors Get Nano-ized," IEEE Spectrum, February 1, 2012.

- A Swarm of Nano Quadrotors, YouTube video, January 31, 2012.

- Caroline Perry, "In new mass-production technique, robotic insects spring to life," Harvard School of Engineering and Applied Sciences Press Release, February 15, 2012

- PC-MEMS Pop-up Icosahedron, YouTube video, November 18, 2011.

Permanent Link to this article

Linked Keywords: Engineering; laboratory; lab; university; research; robotics; video clip; robot; snake; pipe; Sunday supplement; Internet; welding machine; automobile; Swan Lake; The Rite of Spring; mechanical; fly-on-the-wall; surveillance; Electronic Frontier Foundation; warrant; combat troops; intelligence-gathering; maxim; knowledge is power; Bletchley Park; Manhattan Project; engineer; University of Pennsylvania; General Robotics, Automation, Sensing and Perception (GRASP) Laboratory; helicopter; acrobatics; nanotechnology; YouTube video; swarm; synchronized; electronics; Global Positioning System; GPS; electric power; manufacturing; transportation; unmanned aerial vehicle; drone aircraft; Harvard University; School of Engineering and Applied Sciences; KMel Robotics; US quarter; coin sized; bee; monolithic; scaffold; origami; laser cutting; laminate; carbon fiber; Kapton; hinge; titanium; brass; ceramic; adhesive; associate professor; electrical engineering; Robert J. Wood; Wyss Institute for Biologically Inspired Engineering; doctoral candidate; micrometer; yield; planar; three-dimensional; patent; Journal of Micromechanics and Microengineering; graduate student; research assistant; U.S. Army Research Laboratory; National Science Foundation.