Paper Accelerometer

March 10, 2011

I mentioned the

piezoresistance of

carbon in a

previous article (Piezomolecular Effect, February 22, 2011).

Thomas Edison discovered that sound pressure can change the resistance of carbon particles placed between conducting plates. The mechanism for action is that the pressure acting on the loose particles causes more contacts through which

current can flow.

Carbon is inexpensive. A research group from

Harvard University has decided to team inexpensive carbon with something that's also cheap,

paper, to produce a paper

accelerometer. A brief article on the device, produced by

George Whitesides' group, was published online in the

IEEE Spectrum.[1] A few other "mirror"-type sites republished the story, but not much additional information is available on the Internet. Fortunately, the device is so simple that not much information is needed to reproduce this device, as I'll show.

The device is a simple

cantilever beam with a conducting carbon trace in the region where the beam joins to its mounting. This is by design, since the maximum surface

strain occurs at that point when the beam is end-loaded. Since the people who built this are

chemists, they used thick

chromatography paper, something they would find in their laboratory. There are

silver conductors on the mounting tab, and a U-shaped

screen-printed carbon trace that enters the high-strain region. Carbon inks are used for some printed circuitry, as are silver-filled epoxies. You can find a photograph of the

dime-sized device

here.[1]

As expected, bending the cantilever changes the resistance of the carbon trace. Whitesides admits that you get what you pay for, and such a device will in no way replace micromachined silicon. His observation was echoed by a few internet commentators,[2] but there may be some applications where high precision is not required and price is the key. Here are a few problems I can surmise off the top of my head, along with some obvious solutions.

Temperature-induced error. If the compensating elements in a bridge circuit are also carbon, such an error will cancel-out.

Non-linearity. Putting a carbon trace on both sides of the cantilever will allow linearization.

Hysteresis and cycle fatigue. The paper must be of a certain quality. Recycled paper, which has too many short fibers, should be avoided. Paper loaded with polymer fibers might be better.

Humidity. Humidity will change the mechanical properties of the paper. As someone who's done chemical photography, I know that resin-coated paper will keep water out.

Reproducibility is an essential part of the scientific process, and such a simple device begs to be copied. So, armed with a

No. 2 pencil, a

cardboard index card and some

binder clips, that's what I did.

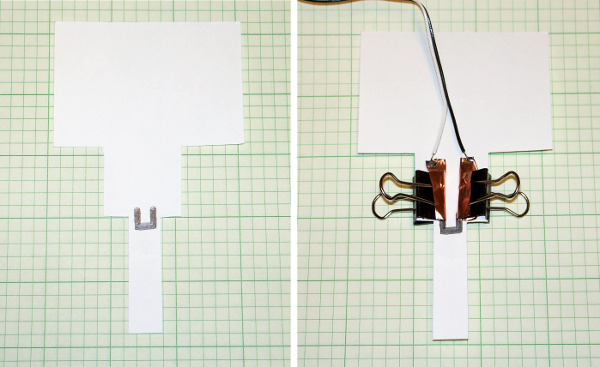

As the photograph shows, my device is a little larger than dime-sized, but only for convenience. The index card was measured to be 0.006-inches thick. The large squares in the background are an inch on a side, and twenty five small squares fill a square inch. I cut a cantilever in the index card, put a heavy trace of carbon with the pencil in the high-stress area, and then made contact through the binder clips (with a little assist from some

copper foil).

Left - A small U-shaped trace of carbon is applied using a No. 2 pencil. Right - Binder clips and copper foil make electrical contact. The large squares are an inch on a side, and the cardboard is 0.006-inch thick.

Since I'm an electronics person, I have a

digital multimeter that measures resistance. I remember paying $8.00 for it at a

hamfest. The graph below shows my data. There's quite a change in resistance when the cantilever is arched upwards, when the carbon trace is compressed, but not much the other way. One source of error I needed to eliminate was bending of the device across the axis of the beam. This caused a large change in resistance, since a strain is applied to the bottom of the "U." This made me realize that these materials would work as pressure sensors, also.

Performance of the simple carbon-based piezoresistive paper cantilever sensor.Graphics via Gnumeric

The cost of the

Large Hadron Collider is about ten billion dollars. Even if you include the price of the multimeter and the entire pencil, my experiment rings up at about ten dollars. Perhaps there should be a new unit in science, called the LHC, which is the price of a large

physics experiment. My experiment has a value of 10

-9 LHC. Perhaps that applies to both monetary

and scientific value.

References:

- Prachi Patel, "Paper Accelerometer Could Mean Disposable Devices," IEEE Spectrum Online, February, 2011.

- Harvard Professor Creates Paper Accelerometer, Slashdot, February 14, 2011.

- George Whitesides Homepage at Harvard University.

- George Whitesides biography and a video presentation at the Kavli Foundation web site.

Permanent Link to this article

Linked Keywords: Piezoresistance; carbon; Thomas Edison; electric current; Harvard University; paper; accelerometer; George Whitesides; IEEE Spectrum; cantilever beam; strain; chemist; chromatography; silver; electrical conductor; screen printing; dime-sized; reproducibility; No. 2 pencil; card stock; cardboard; binder clip; copper; digital multimeter; hamfest; Gnumeric; Large Hadron Collider; physics.