Flow Batteries

March 12, 2015

Winter is an

energy-intensive time of year at

Tikalon's home in the

Northeastern United States. The

days are shorter, leading to a longer daily interval of

artificial lighting. The newer

LED lamps have reduced

energy cost considerably, but

home heating requires a lot of energy. About 250

therms is needed to heat my house during the course of a cold winter

month. A therm is about 100

cubic feet of

natural gas; and, depending on location, a therm costs slightly more, or less, than a

dollar.

There's also considerable expenditure of

human energy involved in

snow removal. Fortunately, I have a powerful

snow blower. This nine

horsepower blower allows the clearing of my

driveway, and the driveways of two

neighbors, in just an

hour after a typical eight

inch snowfall. The traditional

conversion factor for a horsepower is 746

watts, so a nine horsepower engine is equivalent to more than six

kilowatts! When my home

boiler and snowblower are operating simultaneously, I'm a major contributor to

greenhouse gas emission.

I'm an advocate of

renewable energy, having written quite a few articles on this topic over the years. While

hydroelectric and tidal power plants are renewable energy sources with fairly constant output, the supply of energy from other renewable energy sources is sporadic. You can't get that much solar energy on cloudy days, and there's none at

night.

Wind turbines are capable of supplying power at night, but only when the

wind blows. You need to

store energy so it will be available for later use.

Here's a list of articles on energy storage from this blog:

• Flywheel Energy Storage, July 21, 2011

• Wind-Up Toys, August 5, 2011

• Potential Energy Storage, February 15, 2012

• Flow Batteries, July 18, 2012

• Flow Energy Storage, December 12, 2012

• Compressed Air Energy Storage, July 24, 2013

• The Electrical Grid, September 30, 201

While

batteries are used in some energy storage applications, their low

energy density precludes their use when large quantities of energy must be stored.

Gasoline has an energy density of 46.9

kilojoules per

gram, but a

lithium battery will store just 2.5 kilojoules per gram.

There's a proposal for distributed battery storage of

electricity using

electric vehicle batteries,[1] but an improved battery

technology must be developed before batteries are an

economical component for dedicated

electrical grid energy storage.

Flow batteries might be that technology, but the energy density of presently developed

aqueous flow batteries is lower than that of lithium batteries with

LiFePO4 cathodes (about 225

watt-hour/

liter).[2]

Batteries store energy by

chemical reaction. In the case of a

lead-acid battery, it's through the

reversible transformation of the

lead electrodes to lead sulfate. There are some

electrochemical reactions, however, that involve only

electrolyte solutions, so the electrode materials are not changed. A flow battery operates by removing the charged electrolytes from such batteries, storing them in tanks, then replacing them when battery

discharge is required.

A team of

scientists at the

Pacific Northwest National Laboratory has just

published research on a flow battery based on the reaction of

zinc and

iodine, both of which are relatively benign

materials. The battery

half reactions and overall

reaction are as follow:

(I3)- + 2e- ↔ 3I- (cathode)

Zn ↔ Zn2+ + 2e- (anode)

(I3)- + Zn ↔ 3I- + Zn2+ (overall)

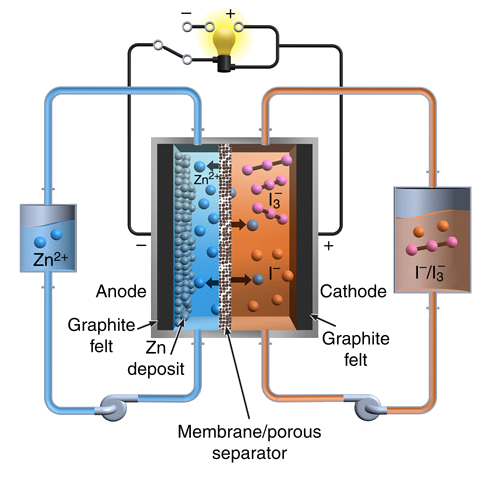

The reaction

potential at the

cathode with respect to a

standard hydrogen electrode is 0.5360

volts, and the potential at the

anode is -0.7626 volts, giving this battery a

cell voltage of 1.2986 volts. A

schematic diagram of this flow battery appears below, along with a photo of the

laboratory demonstration

apparatus for a related

vanadium-redox flow battery.

Schematic diagram of the Pacific Northwest National Laboratory zinc-iodine flow battery. (Fig. 1a of ref. 2, licensed under the Creative Commons Attribution 4.0 International License.)

Go with the flow.

Flow battery construction is easy, as this laboratory demonstration of a related vanadium-redox flow battery shows.

Note the safe laboratory practice of placing the flasks in a polyethylene tray to mitigate spills.

(Pacific Northwest National Laboratory image.)

In the discharged state, both tanks contain an electrolyte with a

neutral pH mixture of Zn

2+ cations and I

- anions. In a charged state, one tank contains another negative ion,

polyiodide, I

3-, while zinc ions are passed through the

selective membrane to

electroplate as

metallic zinc on the negative electrode.[2,4]

The electrolyte of the zinc-polyiodide flow battery developed by the Pacific Northwest National Laboratory has an

energy density more than two times that of the next-best flow battery and 70% that of a

lithium iron phosphate battery.[4] Says

Wei Wang, an

author of the study and a

materials scientist at PNNL, "Another, unexpected bonus of this electrolyte's high energy density is it could potentially expand the use of flow batteries into mobile applications such as powering

trains and

cars."[4]

The PNNL team has demonstrated a discharge energy density of 167 watt-hour/liter for a nearly neutral pH 5.0 M ZnI

2 electrolyte.[2] In

theory, a more highly

concentrated electrolyte could discharge up to 322 watt-hour/liter.[4]

Electric cars use about 350 watt-hours for each

mile of

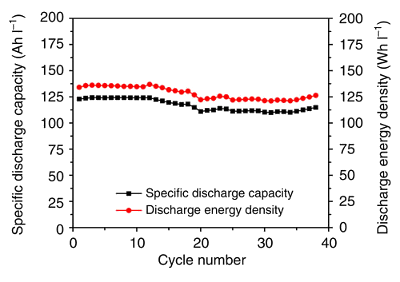

city driving.[4] The following

graph shows the

cycling performance of the zinc-iodine flow battery using

Nafion 115 as the membrane, a 3.5 M ZnI

2 electrolyte, and a

current density of 10

mA/

cm2.[2]

Cycling performance of the zinc-iodine flow battery.

(Fig. 2c of ref. 2, licensed under the Creative Commons Attribution 4.0 International License.)

Even at a lower energy density, the zinc-iodine flow battery has some advantages over lithium cells. First, lithium batteries are not completely

fire-safe, while the water-based (see exception, below) electrolyte in the flow cell won't ignite.[4] Also, the electrolyte isn't

acidic, so it's less

hazardous than the electrolyte in other flow batteries, and in other batteries.[4] In order to extend the operating

temperature range, and minimize zinc

dendrite formation, the PNNL team added

ethanol to the electrolyte. This allowed operation from -20 to 50

°C.[2-4]

Zinc dendrites are a problem, since they can puncture the membrane, so the PNNL team is trying other

alcohols and additives to see whether the dendrites can be eliminated, and the team is scaling-up to a 100-watt-hour system.[4] This research was funded by the

US Department of Energy.[4]

References:

- Mark Chediak, "Musk Battery Works Fill Utilities With Fear and Promise," Bloomberg, December 4, 2014.

- Bin Li, Zimin Nie, M. Vijayakumar, Guosheng Li, Jun Liu, Vincent Sprenkle, and Wei Wang , "Ambipolar zinc-polyiodide electrolyte for a high-energy density aqueous redox flow battery," Nature Communications, vol. 6, article no. 6303 (February 24, 2015), doi:10.1038/ncomms7303. This is an open access article, with a PDF file available, here.

- Supplementary information for ref. 2 (850 kb PDF file).

- Frances White, "New flow battery to keep big cities lit, green & safe," Pacific Northwest National Laboratory press release, February 25, 2015.

- How Flow Batteries Work, Pacific Northwest National Laboratory YouTube video, February 25, 2015.

Permanent Link to this article

Linked Keywords: Winter; energy; year; Tikalon; Northeastern United States; day; artificial lighting; LED lamp; cost; central heating; home heating; therm; month; cubic foot; cubic feet; natural gas; dollar; human; snow removal; snow blower; horsepower; driveway; neighbor; hour; inch; snowfall; conversion factor; watt; boiler; greenhouse gas emission; renewable energy; hydroelectricity; hydroelectric; tidal power; renewable energy sources; solar energy; cloud; cloudy; night; wind turbine; electric power; wind; flywheel energy storage; wind-up toys; potential energy storage; flow batteries; flow energy storage; compressed air energy storage; electrical grid; battery; energy density; gasoline; joule; kilojoule; gram; lithium battery; electricity; electric vehicle; technology; economics; economical; electrical grid; aqueous solution; lithium iron phosphate battery; LiFePO4; watt-hour; liter; chemical reaction; lead-acid battery; reversible process; chemical transformation; lead; electrode; lead sulfate; electrochemistry; electrochemical; electrolyte solution; electric charge; charged; discharge; scientist; Pacific Northwest National Laboratory; scientific literature; publish; research; zinc; iodine; material; half reaction; chemical reaction; electrode potential; cathode; standard hydrogen electrode; volt; anode; electrochemical cell; schematic diagram; laboratory; apparatus; vanadium redox battery; Creative Commons Attribution 4.0 International License; polyethylene; neutral pH; cation; anion; polyiodide; ion exchange; selective membrane; electroplating; electroplate; metal; metallic; energy density; Wei Wang; author; materials science; materials scientist; train; automobile; car; theory; concentration; concentrated; electric car; mile; city; driving; Cartesian coordinate system; graph; charge cycle; cycling; Nafion; current density; ampere; mA; square meter; cm2; flammability; fire-safe; acid; acidic; hazard; temperature; dendrite; ethanol; Celsius; °C; alcohol; US Department of Energy.